Copyright Notice and Disclaimer

© Strumis Limited 2017. All rights reserved.

This document has been prepared by or on behalf of Strumis Limited and all intellectual property rights therein (including without limitation copyright) are reserved by Strumis Limited.

It has been produced and provided for your use only and strictly for the purposes provided. You may not, except with the express prior written consent of Strumis Limited, distribute or commercially exploit the content (in whole, in part and regardless of whether modified or adapted from the original).

Whilst every effort has been made to ensure the accuracy and completeness of the content Strumis Limited does not warrant the content nor does it make any representation in respect thereof. You use the materials at your own risk. Strumis Limited together with each of its group companies disclaims any and all liability in respect thereof including without limitation any losses, damages, claims or expenses you or any third party might suffer or incur as a consequence of your use or reliance upon the content.

Trademarks

The following trademarks are acknowledged:

Microsoft, Windows, Internet Explorer, Word, Excel, Visual Basic and all other trademarks that are registered trademarks of Microsoft Corporation.

Edition notice

This manual is intended for use with version 10.1 and later of the STRUMIS software package from STRUMIS Limited.

Support

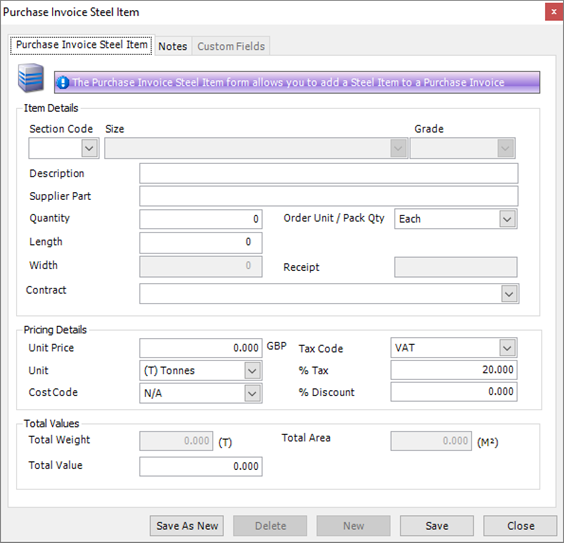

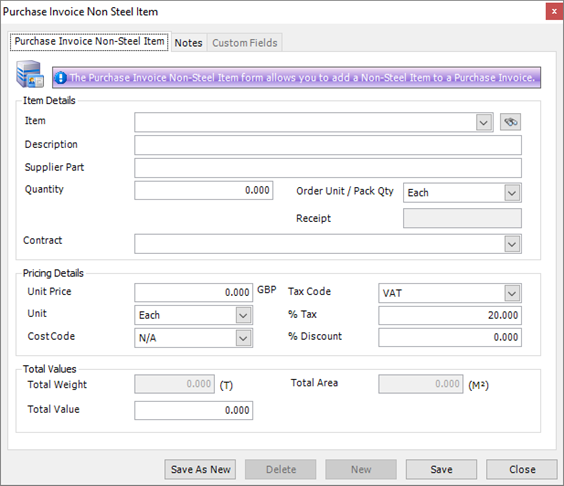

Please direct any questions as follows:

§ For licensing issues, please contact:

licensing@strumis.com

+44 (0) 1332 545800

§ In the UK, for issues other than licensing issues, please contact:

uk.support@strumis.com

+44 (0) 1332 545804

If you are not in the UK, please contact your nearest STRUMIS office or distributor. See our website at www.STRUMIS.com for more information.

Contents

Contents

Welcome to STRUMIS

Chapter 1

Getting started with STRUMIS

Log in to STRUMIS

Find your way around

Work with forms

Work with grids

Work with records

Create a record

Find and edit an existing record

Add notes to a record

Define custom fields for a record

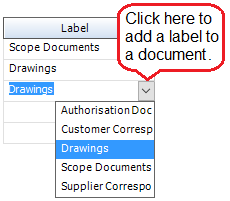

Attach external documents to a record

View basic information about a record

Delete a record

Work with reports

What's next?

Chapter 2

Managing your customers

About customers

Create a customer record

Import customer records

Customer reports

Find and edit a customer record

Customer reports

What's next?

Fields and buttons

Chapter 3

Enquiries and quotations

About enquiries and quotations

Create an enquiry

Set up a parent enquiry

Add customer contacts

Create and print a quotation

Find and edit an enquiry

Enquiry reports

What's next?

Fields and buttons

Chapter 4

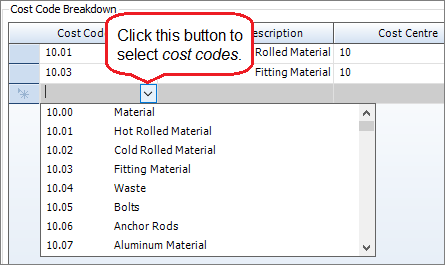

Producing estimates

About estimates

Create an estimate

Add a subsection to the estimate

Add a steel item to the subsection

Add labour for a steel item

Add a fitting to a steel item

Add a non steel item to the subsection

Add a free line item to the subsection

Add an assembly to the subsection

Batch update take-off or BOQ lines

Move items to another subsection

Add extras

Import an estimate

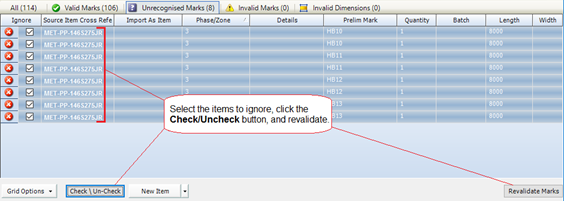

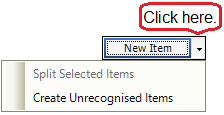

Resolve unrecognised items

Find and edit an estimate

Estimate reports

What's next?

Fields and buttons

Chapter 5

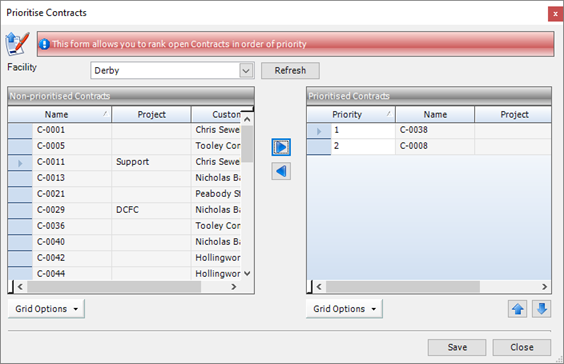

Managing contracts

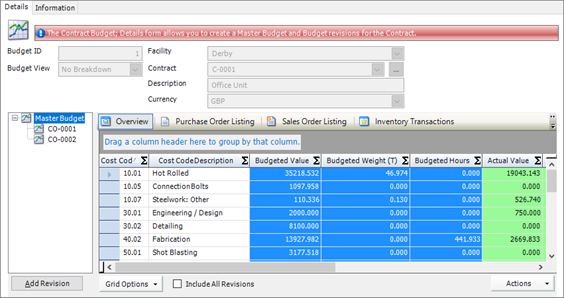

About contracts, budgets and scope changes

Contracts

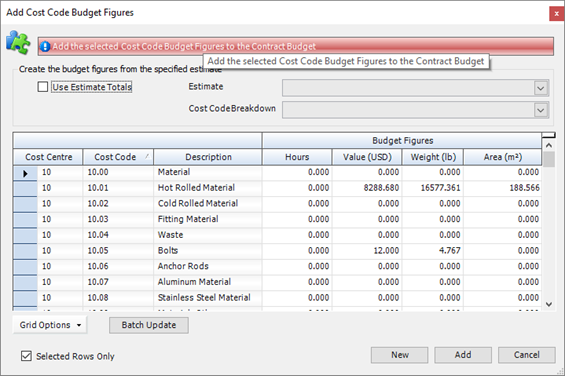

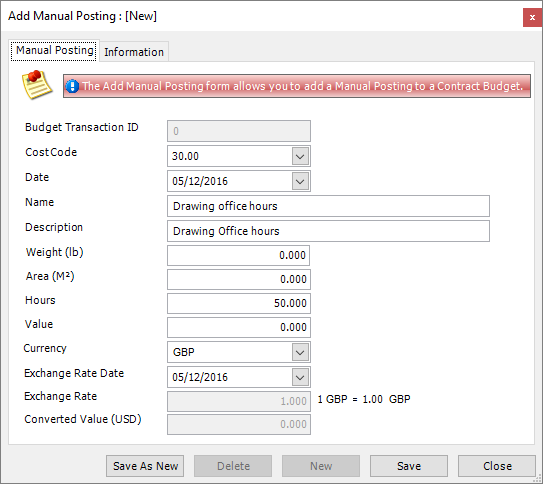

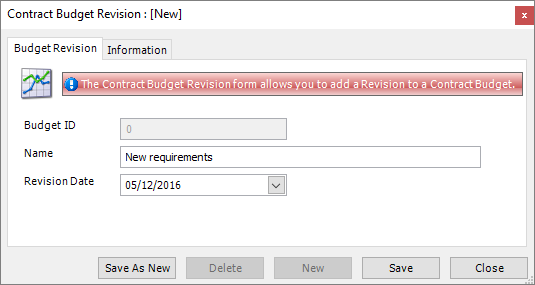

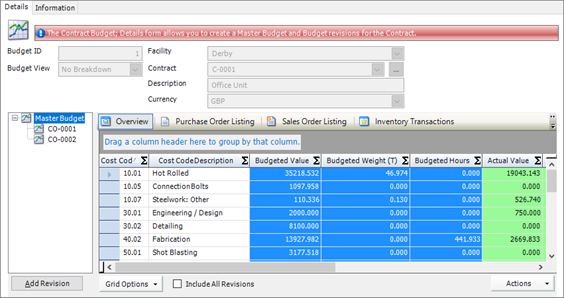

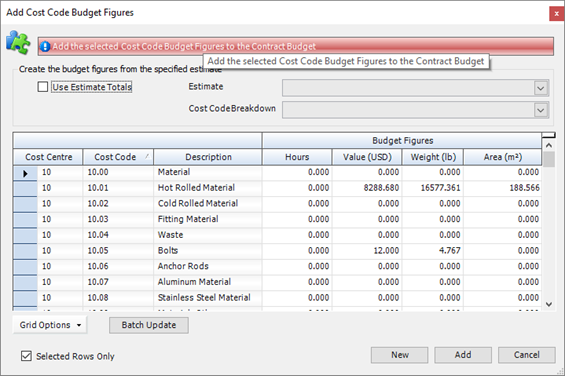

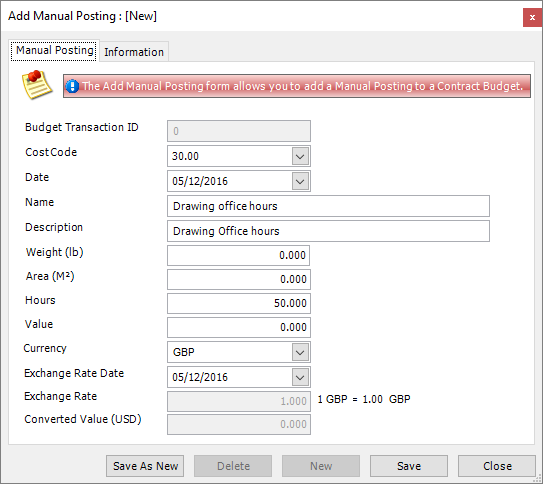

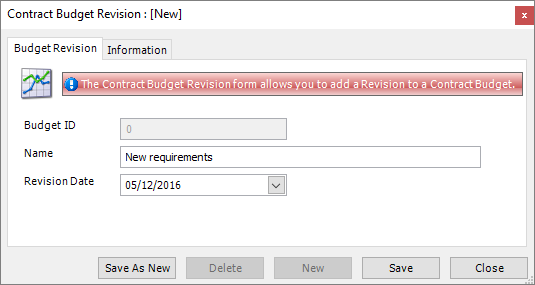

Contract budgets

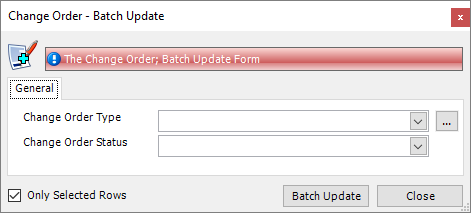

Change orders

Chapter 6

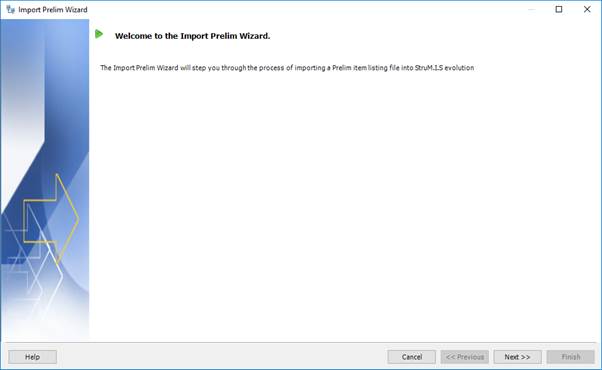

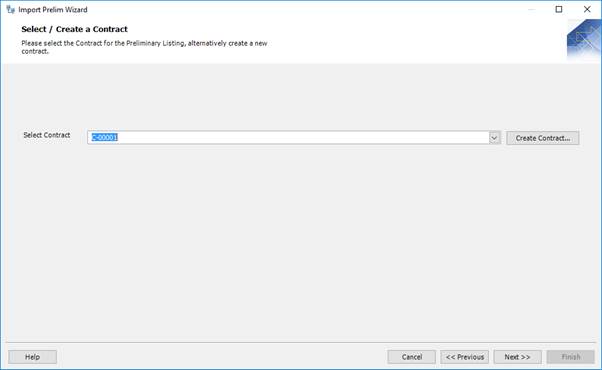

Working with preliminary lists and preliminary nesting and ordering

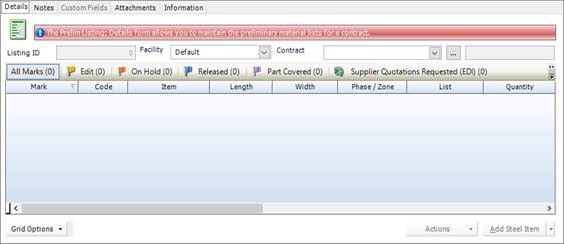

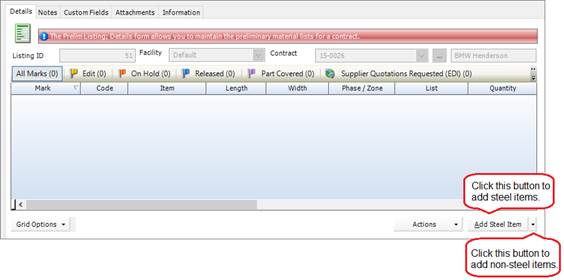

Preliminary listing

Preliminary nesting and ordering

Chapter 7

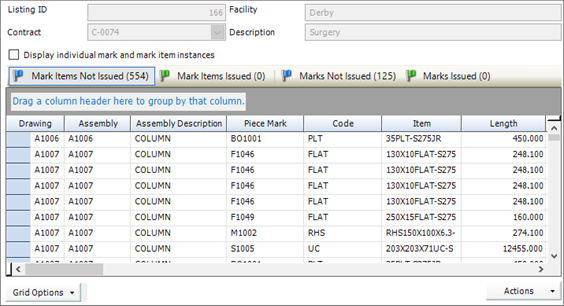

Working with detailed lists

About detailed lists

Detailed list terminology

Create a detailed list

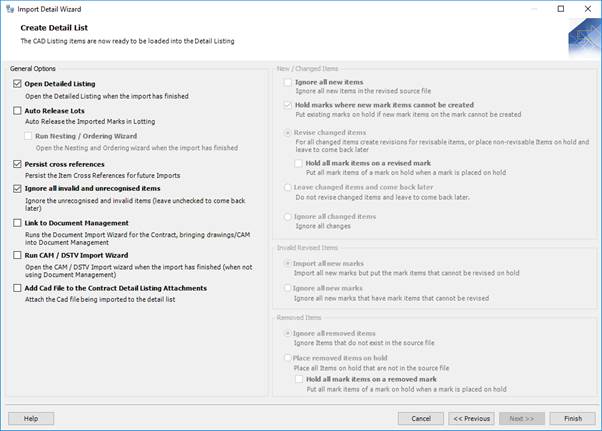

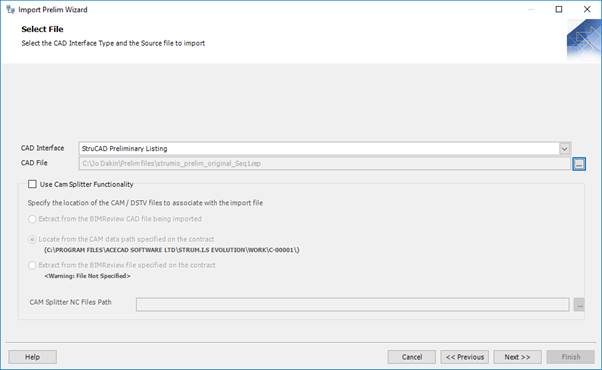

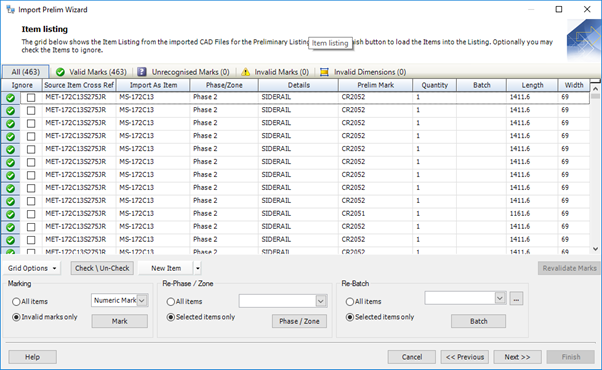

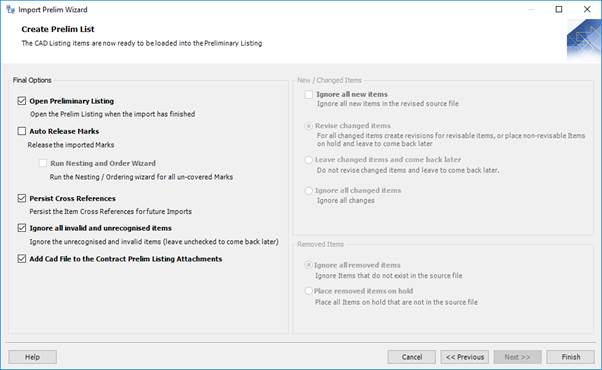

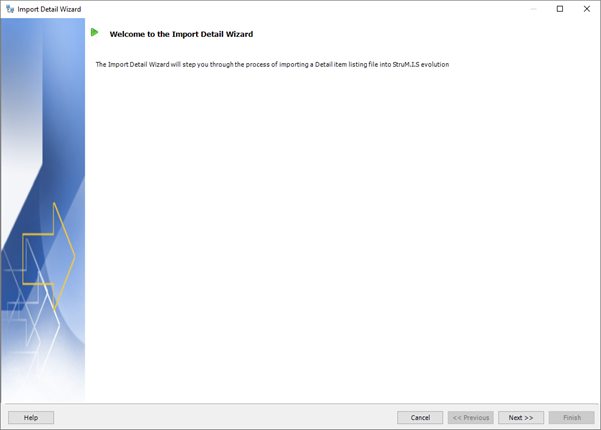

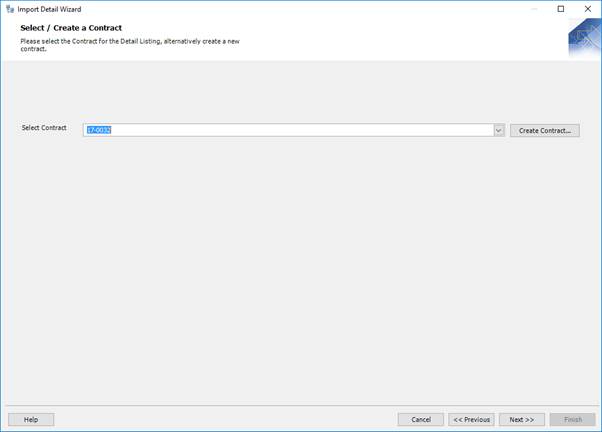

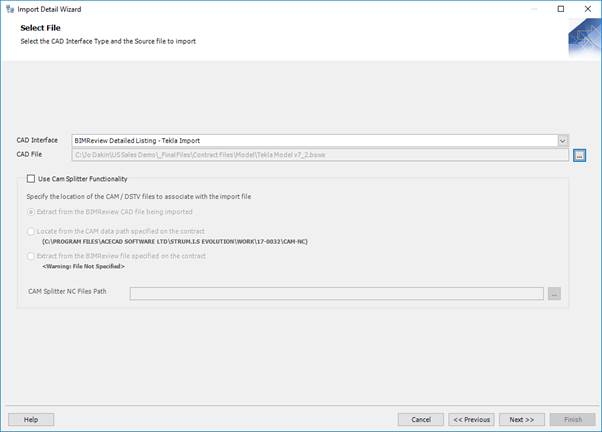

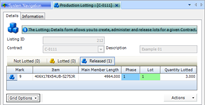

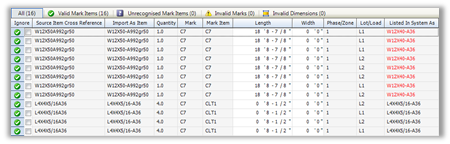

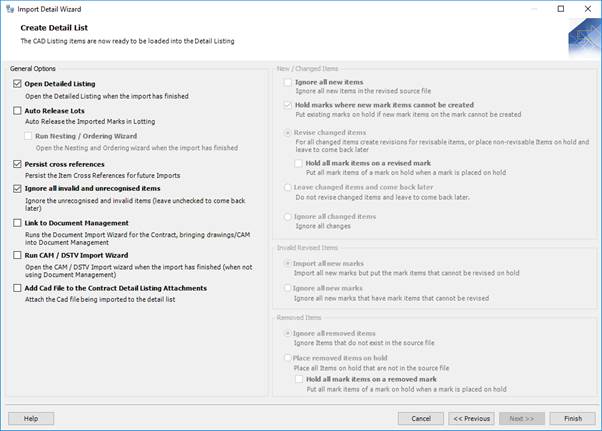

Import a detailed listing from a CAD file

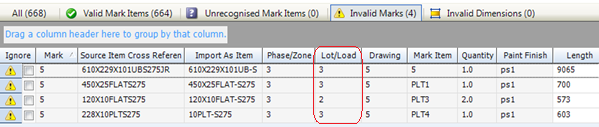

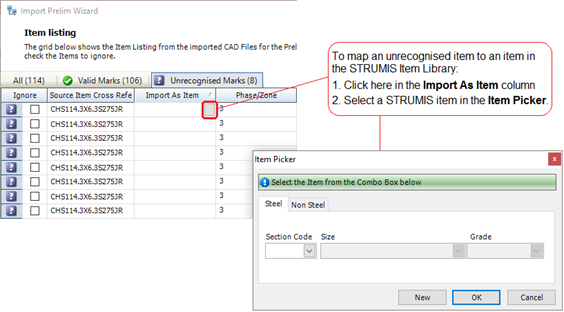

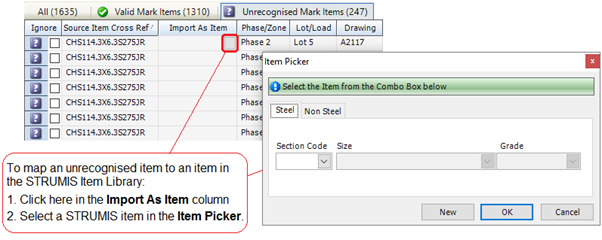

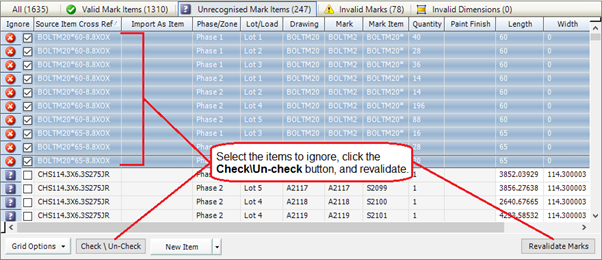

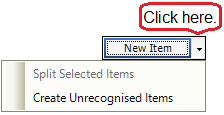

Resolve unrecognised mark items

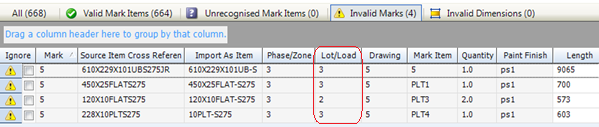

Resolve invalid marks

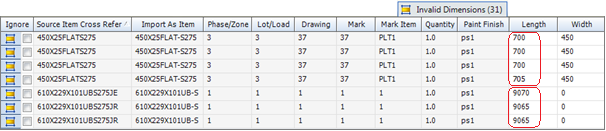

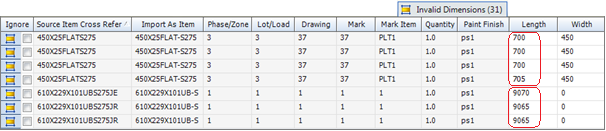

Resolve invalid dimensions

Create a detailed listing

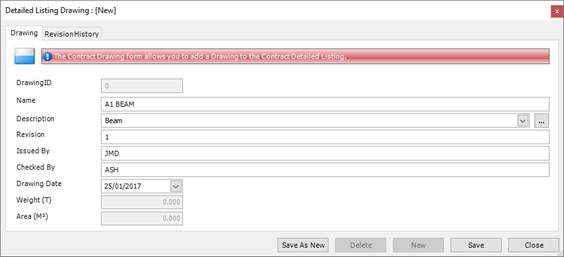

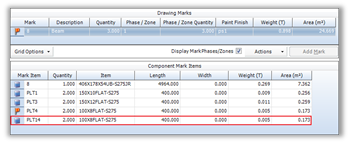

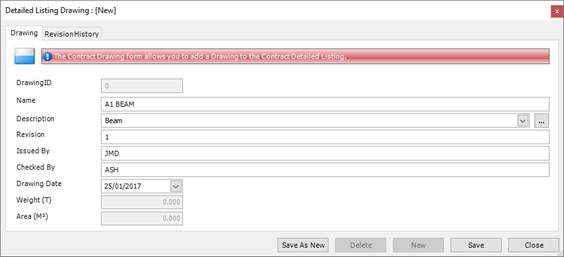

Add a drawing

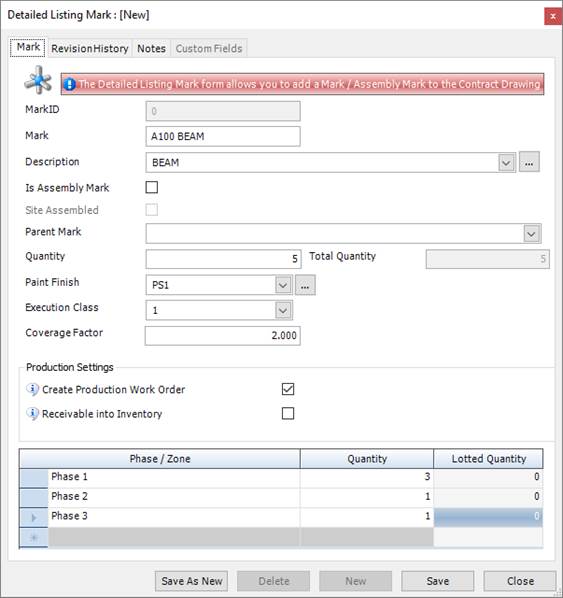

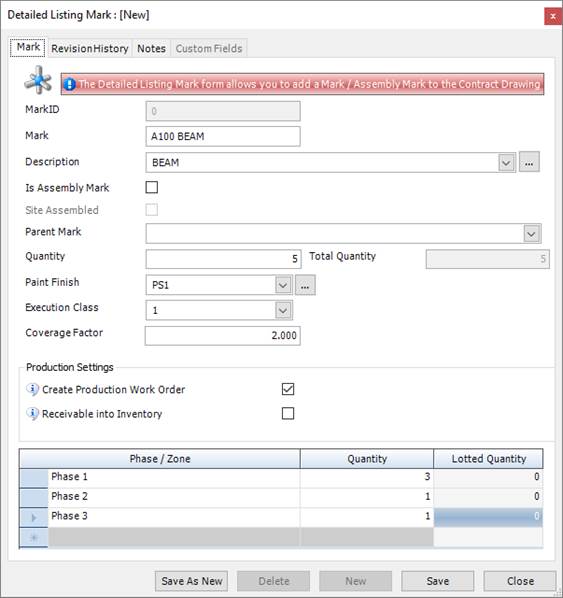

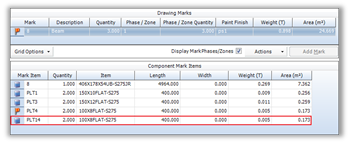

Add a mark

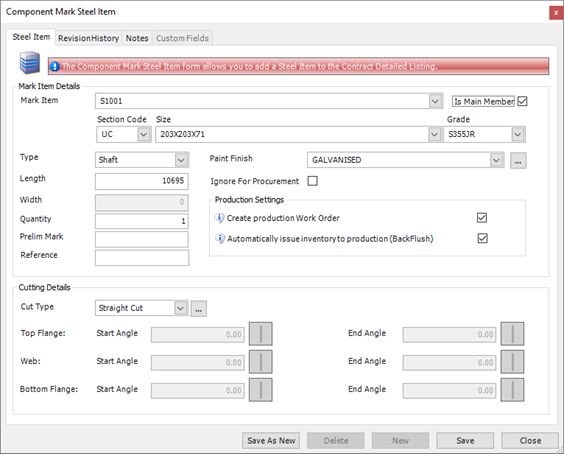

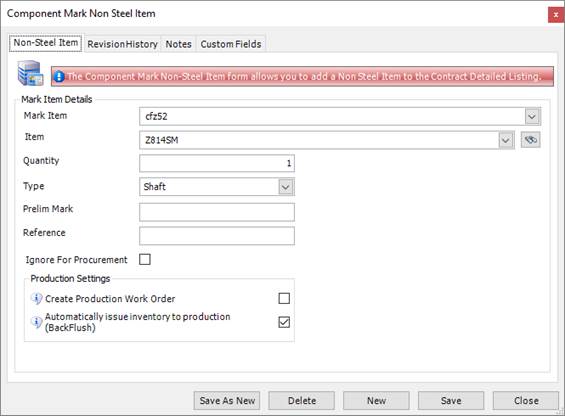

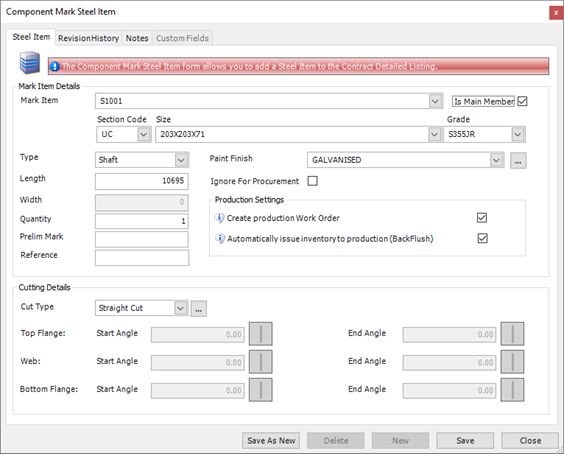

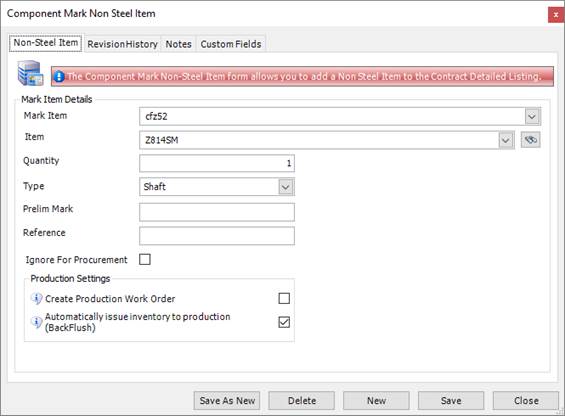

Add a mark item

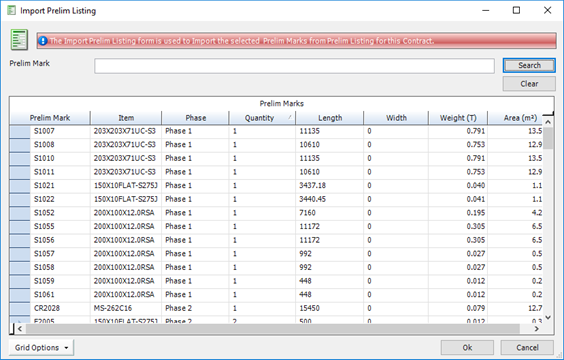

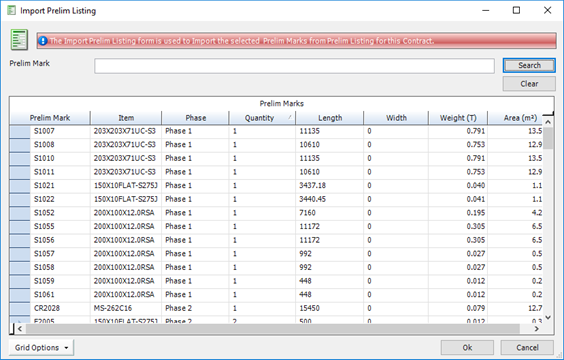

Import marks from a prelim listing

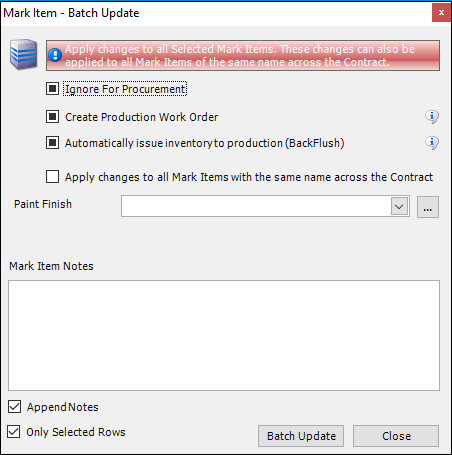

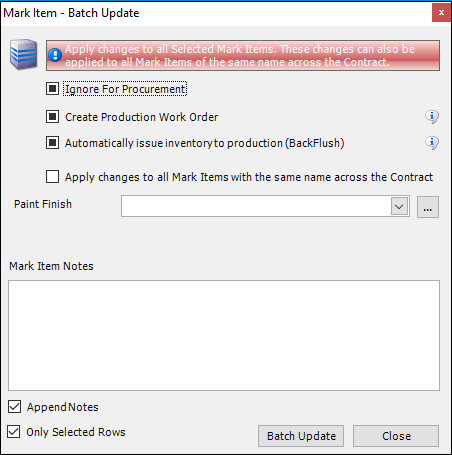

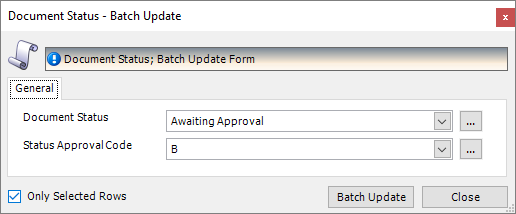

Batch update marks

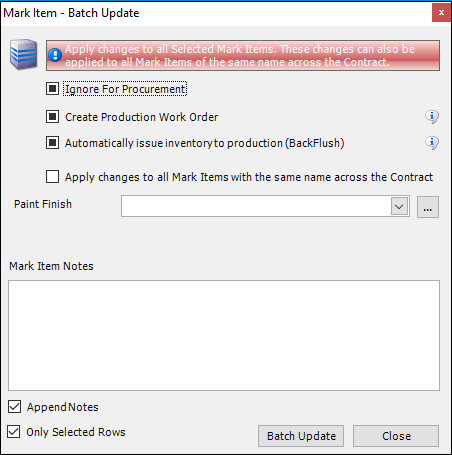

Batch update mark items

Use a black flag to indicate removed items

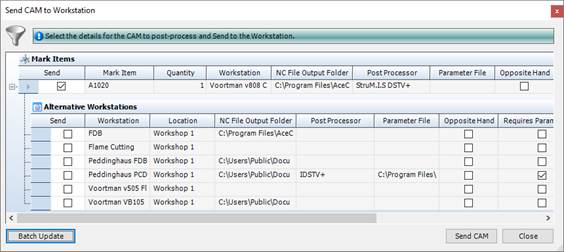

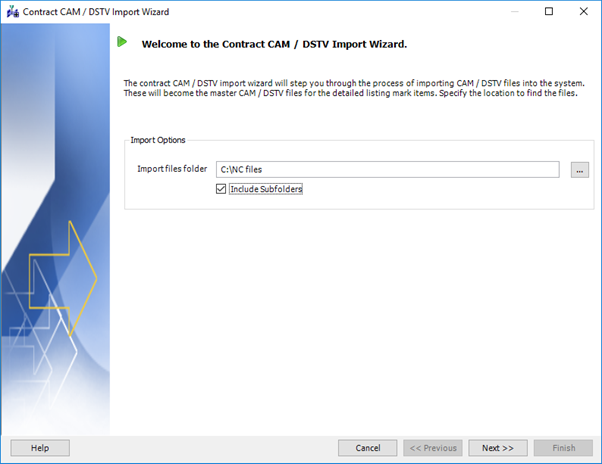

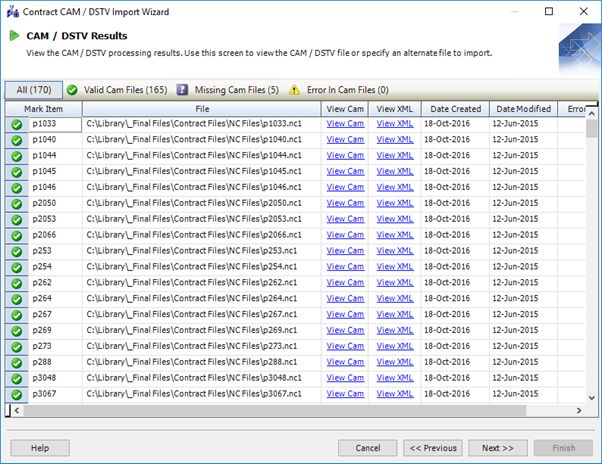

Import CAM/DSTV files

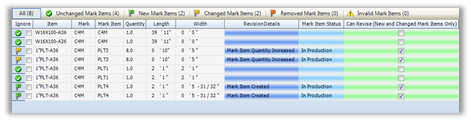

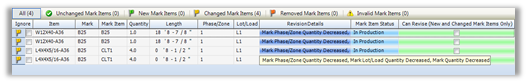

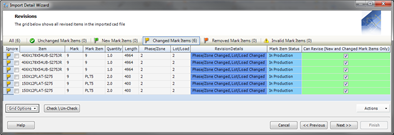

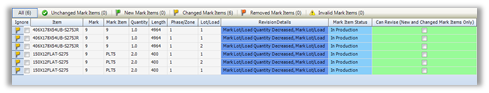

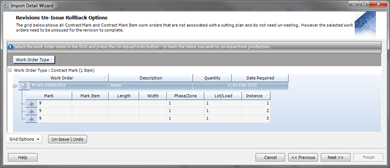

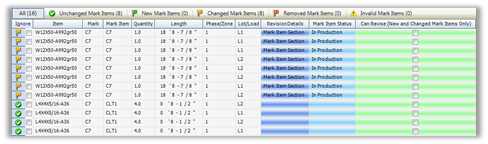

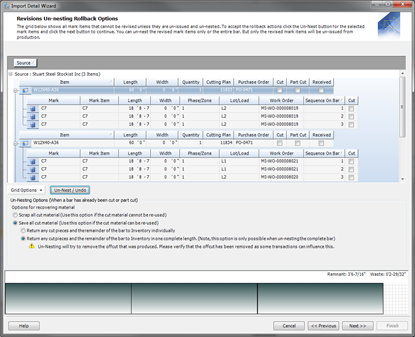

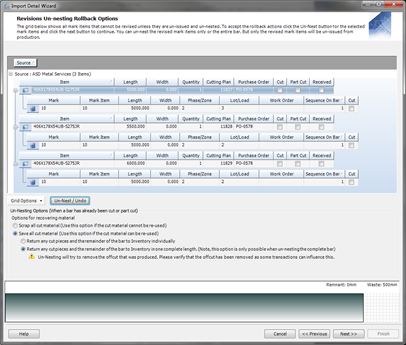

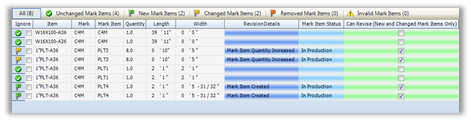

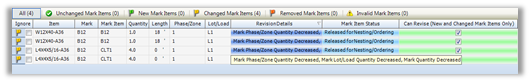

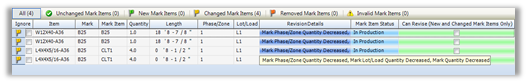

About revising a detailed list

Revision options

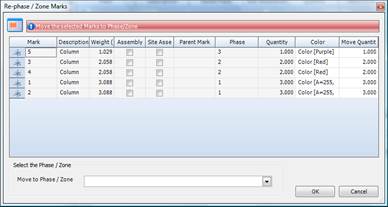

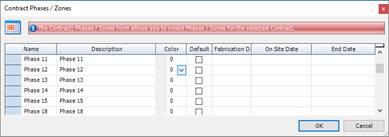

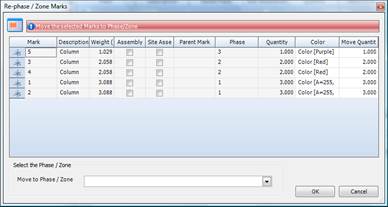

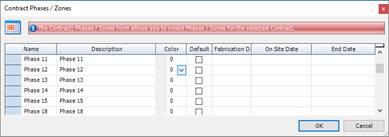

Phase and lot changes

Item (section size) changes

Mark item length changes (linear items)

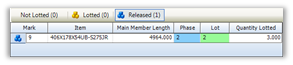

Mark item quantity increase or new mark item added

Mark item quantity decrease

Mark item removed

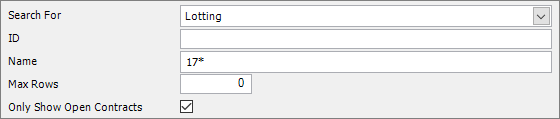

Find and edit a detailed list

Detailed list reports

What's next?

Fields and buttons

Chapter 8

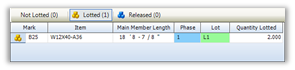

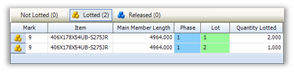

Lotting

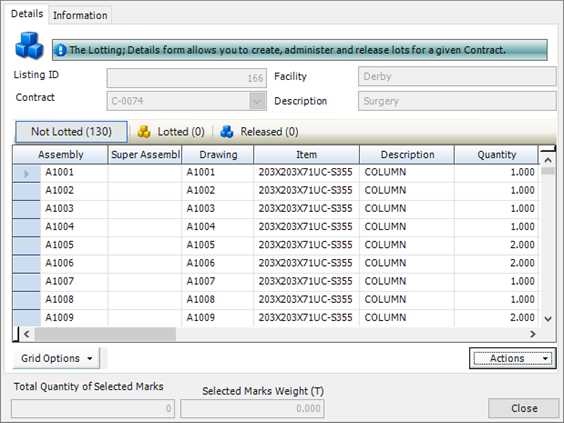

About Lotting

Open lotting information for a contract

Define lots for a contract

Assign marks to a lot

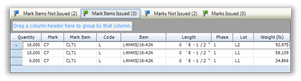

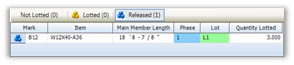

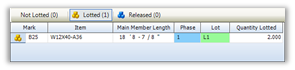

Release marks for nesting and ordering

Batch update marks

Lotting reports

What's next?

Fields and buttons

Chapter 9

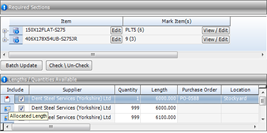

Production nesting and ordering

About production nesting and ordering

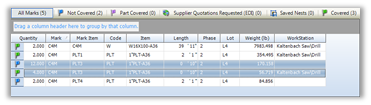

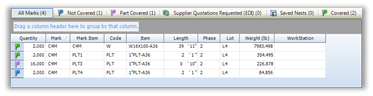

Select mark items to nest

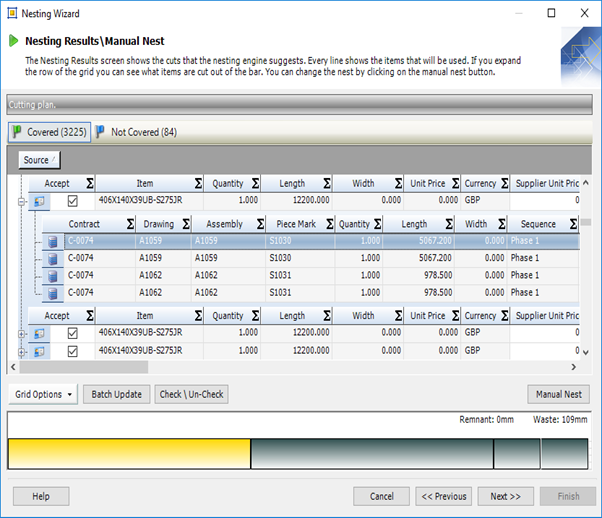

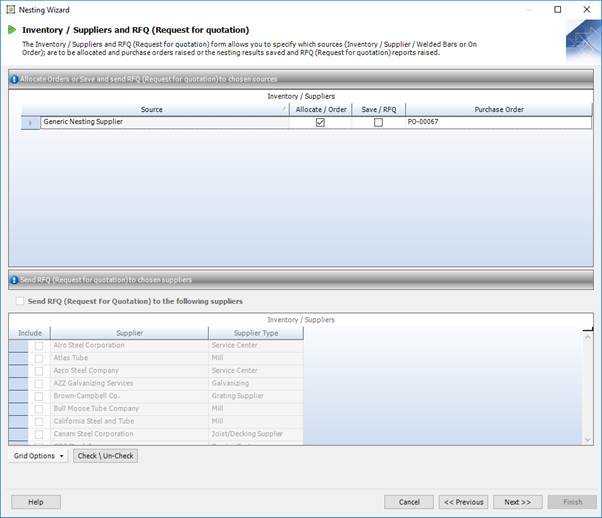

The Nesting Wizard

Manual Nesting

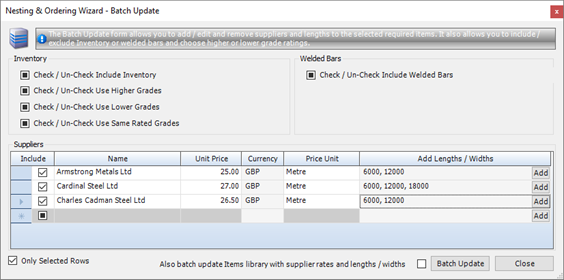

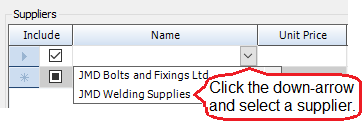

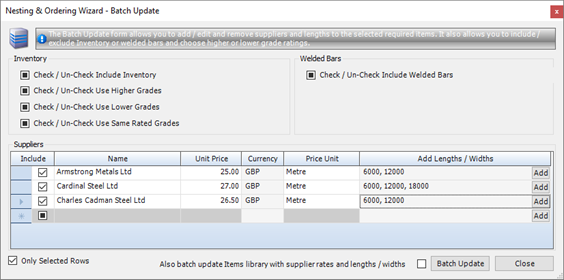

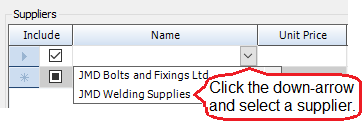

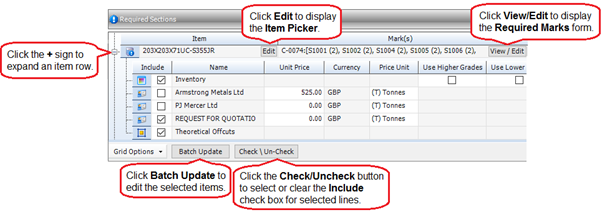

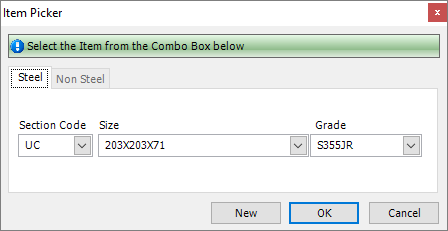

Batch update required sections

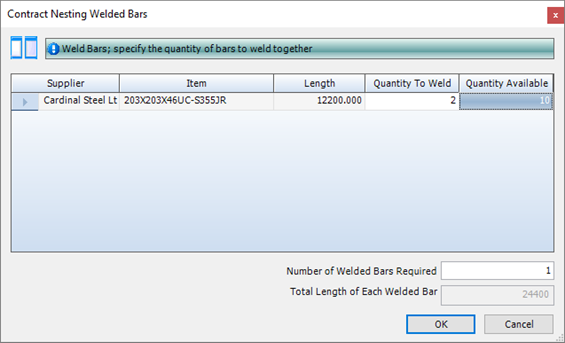

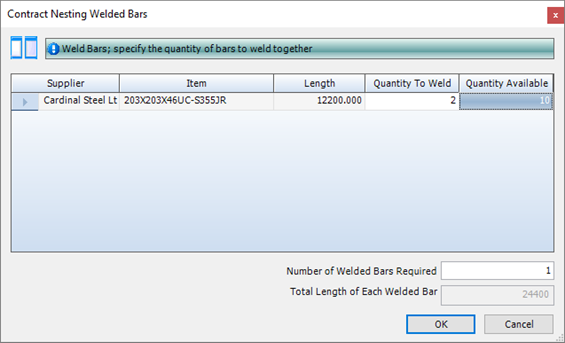

Weld selected lengths together

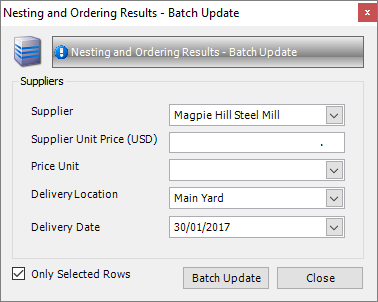

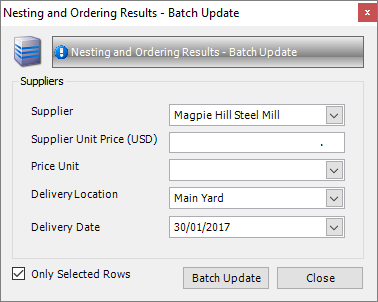

Batch update nesting results

Open a saved nest

Nesting reports

What's next?

Fields and buttons

Chapter 10

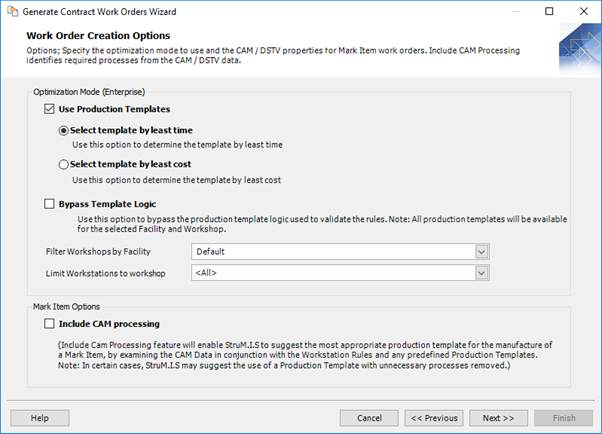

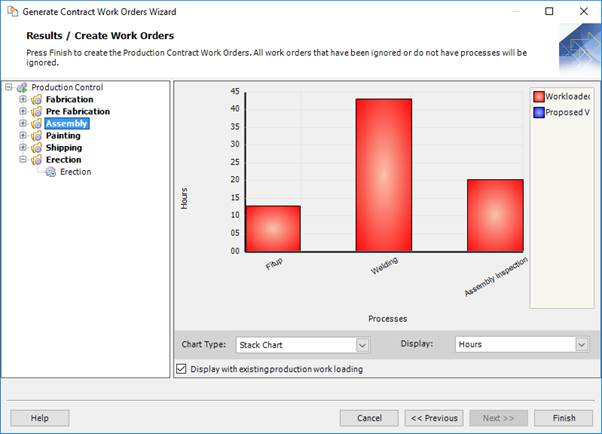

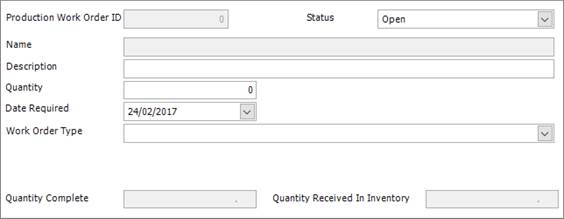

Work orders

About work orders

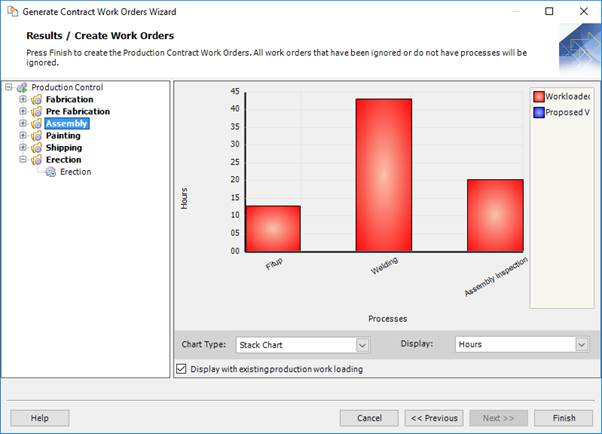

Create a work order using the Generate Contract Work Orders Wizard

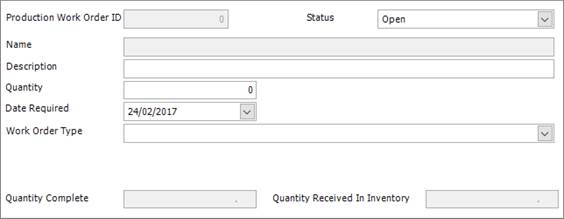

Create a work order manually

Un-issue a work order

Find and edit a work order

Batch update marks

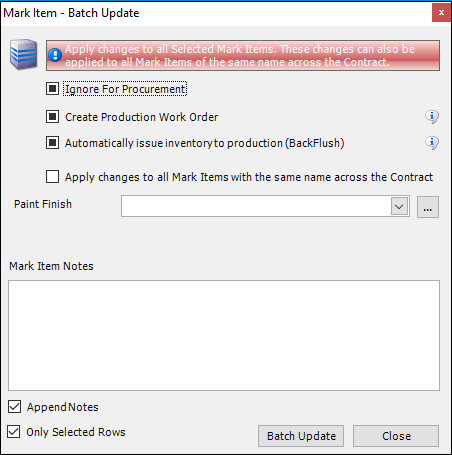

Batch update mark items

Find and edit a work order

Work order reports

What's next?

Fields and buttons

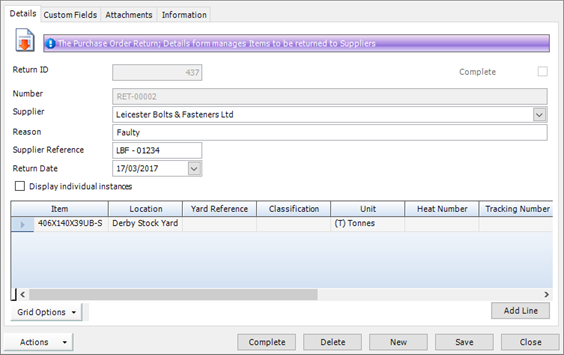

Chapter 11

Ordering, receiving and returning goods

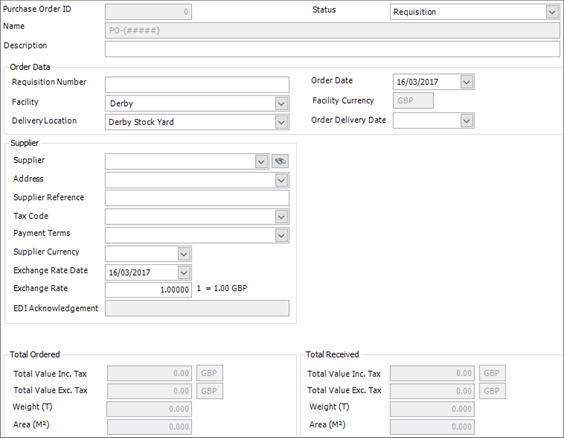

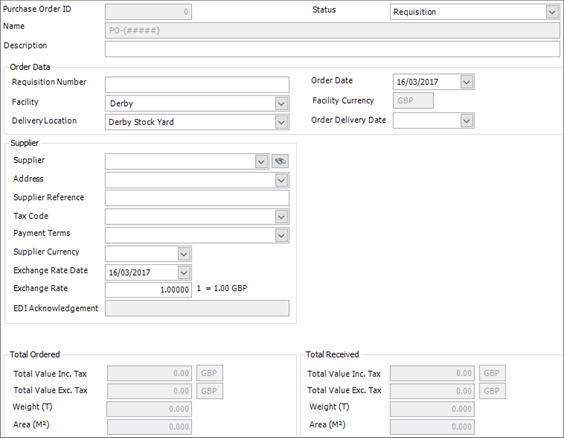

About ordering, receiving and returning goods

Suppliers

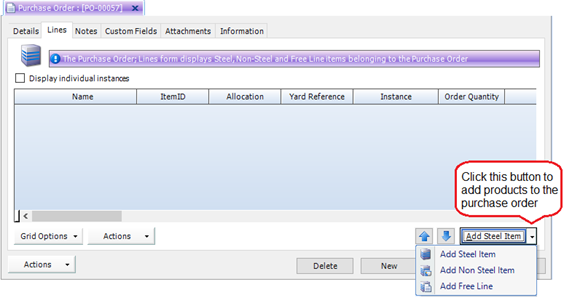

Purchase orders

Purchase order receipts

Purchase invoices

Purchase order returns

Chapter 12

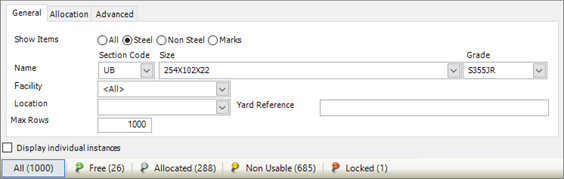

Maintaining the inventory

About the inventory

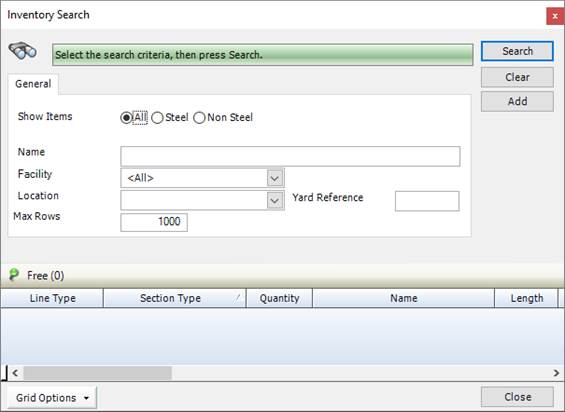

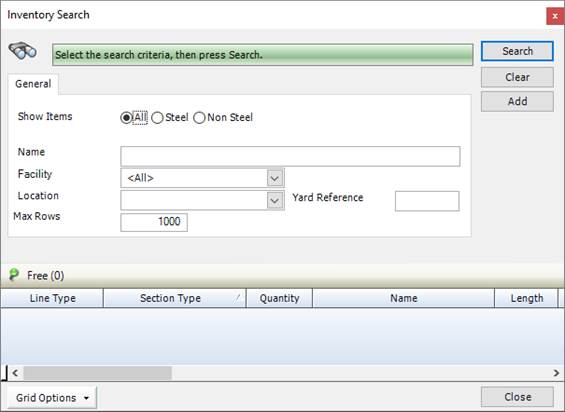

Search the inventory

Transfer inventory

Change classification

Allocate or un-allocate inventory

Exchange bars

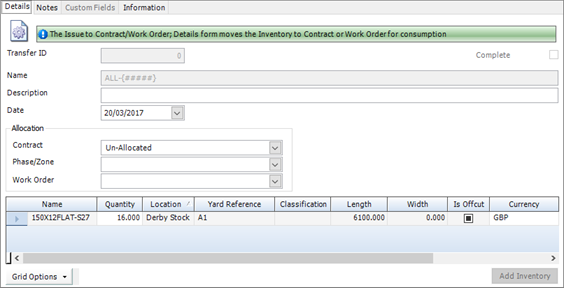

Issue to contract / work order

Add inventory

Inventory adjustment

Inventory batch update

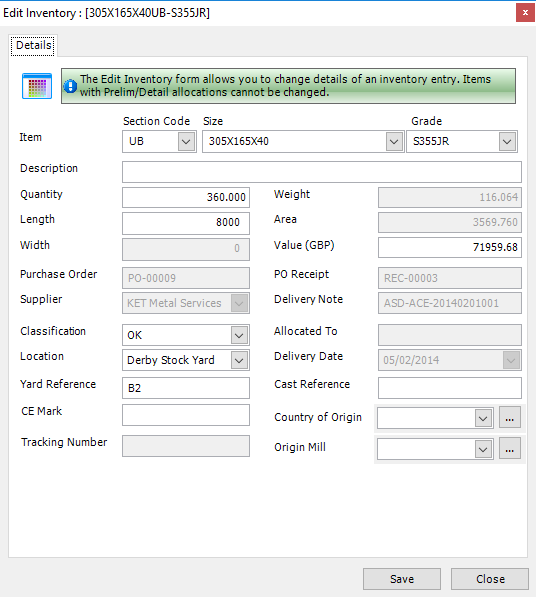

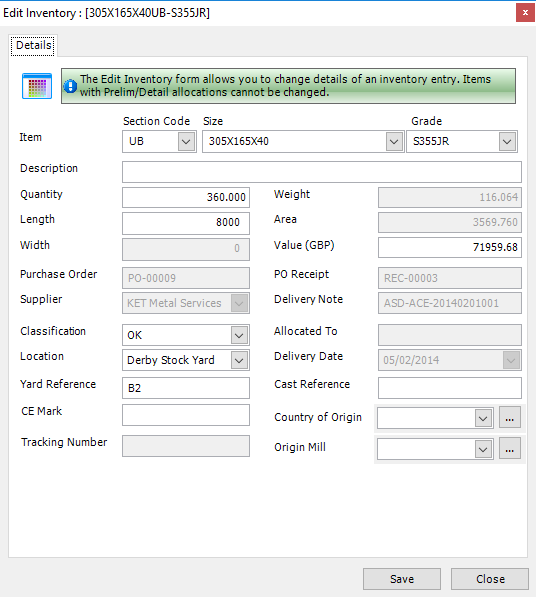

Edit inventory

View item history

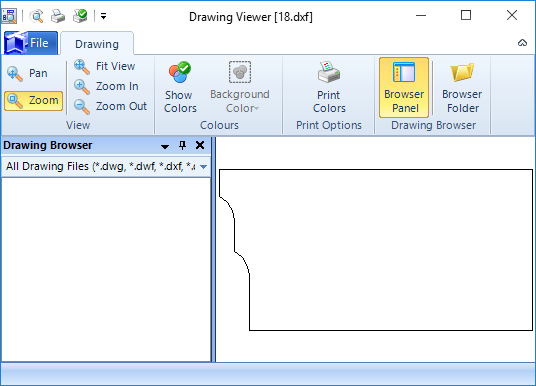

View shape

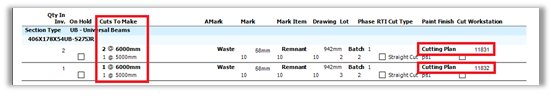

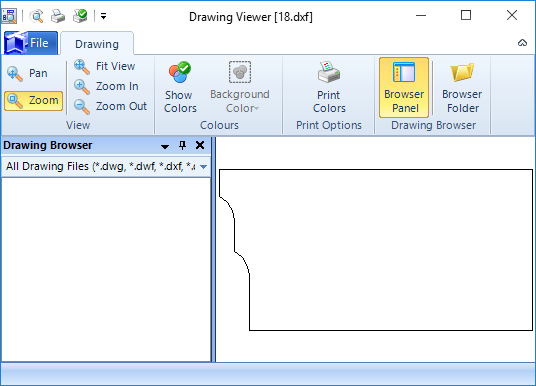

Cutting Plan Viewer

UpdatePricing

Inventory reports

Chapter 13

Production

About production

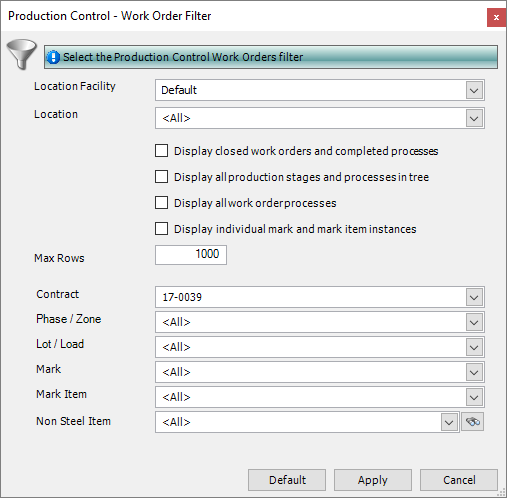

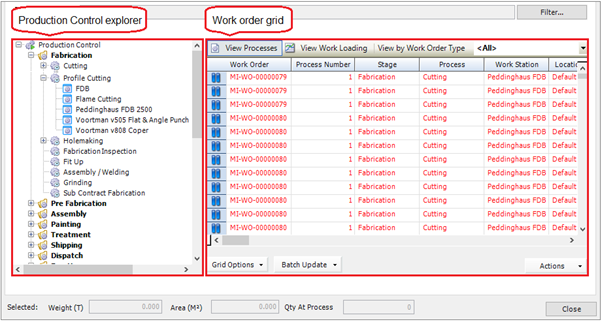

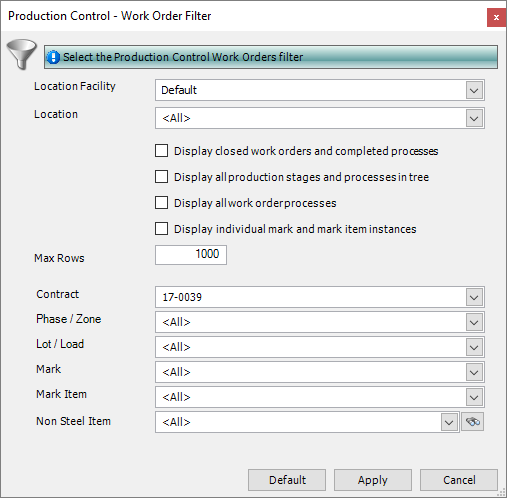

Production control

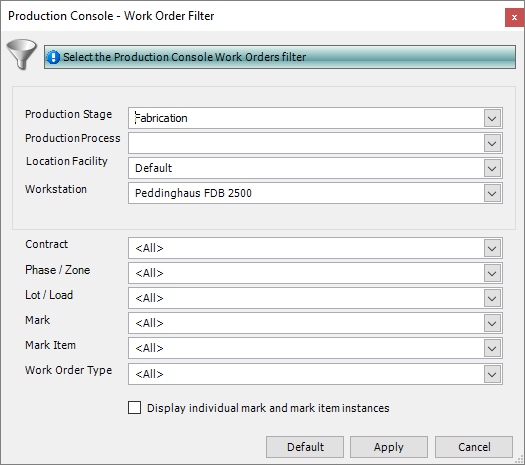

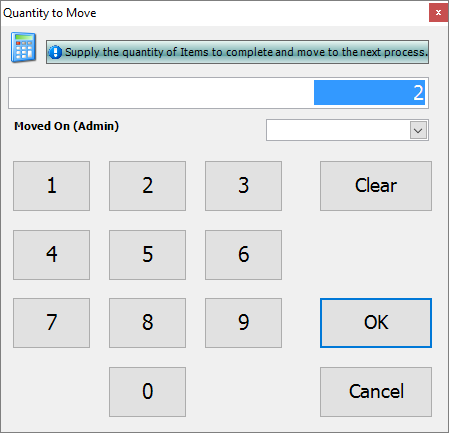

Production console

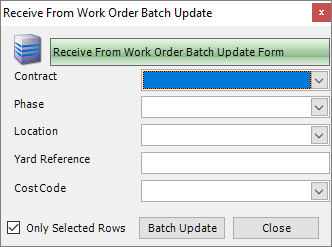

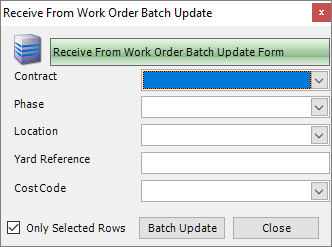

Receive from work order

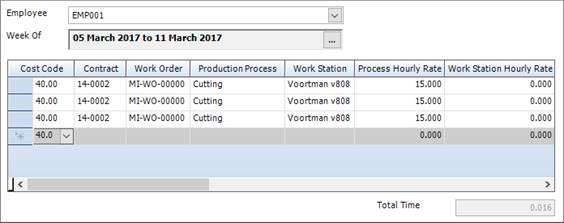

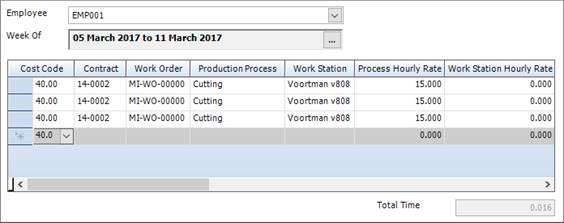

Employee timesheets

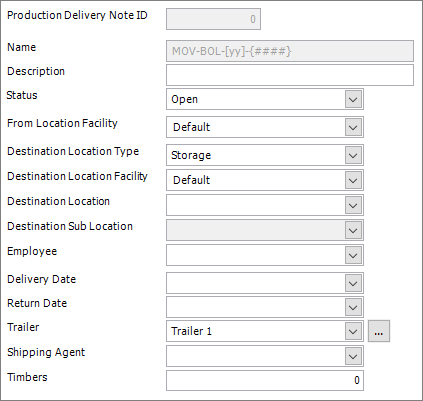

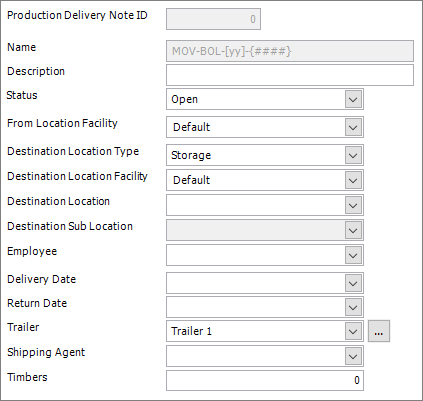

Production delivery notes

Chapter 14

Sales orders, deliveries and invoices

About sales orders, deliveries and invoices

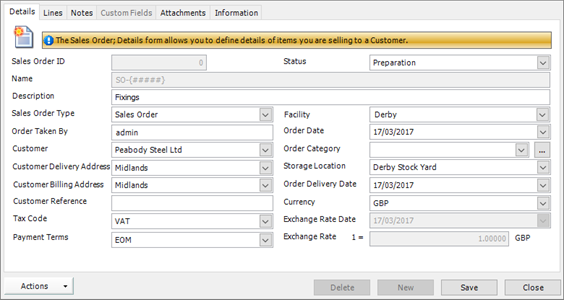

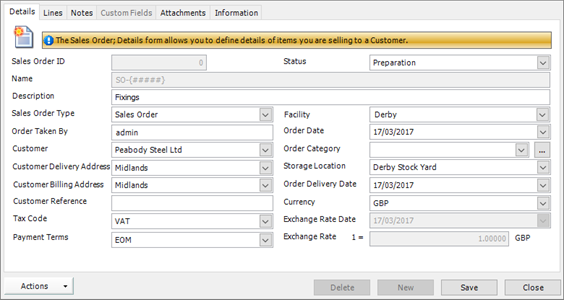

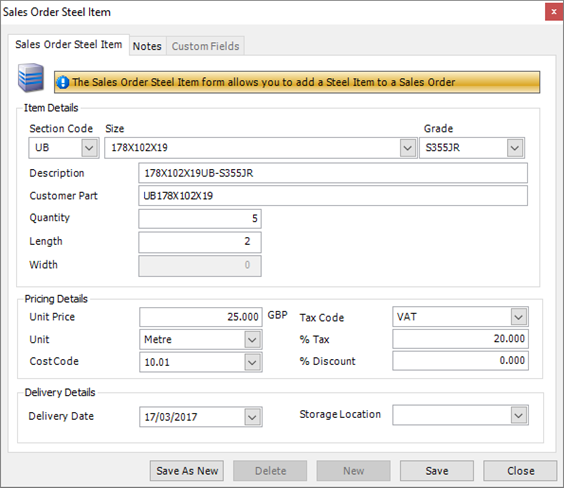

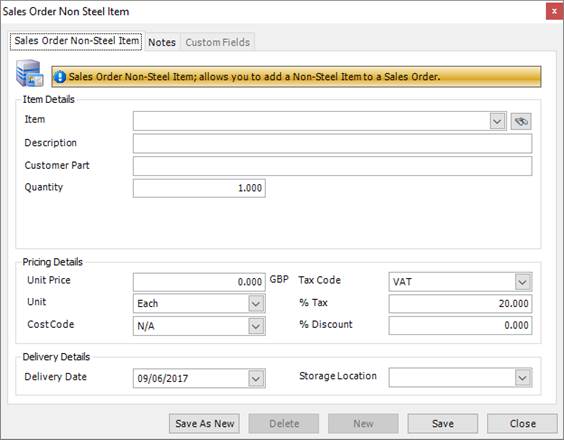

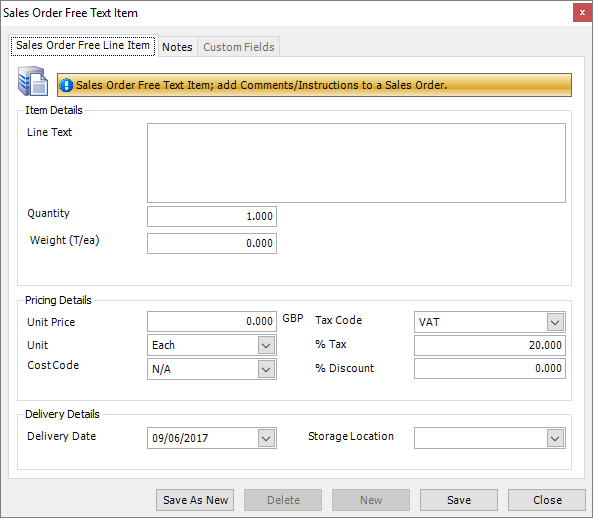

Process a sales order

Sales orders

Sales order deliveries

Sales invoices

Chapter 15

Document management

About document management

Contacts

Documents

Transmittals

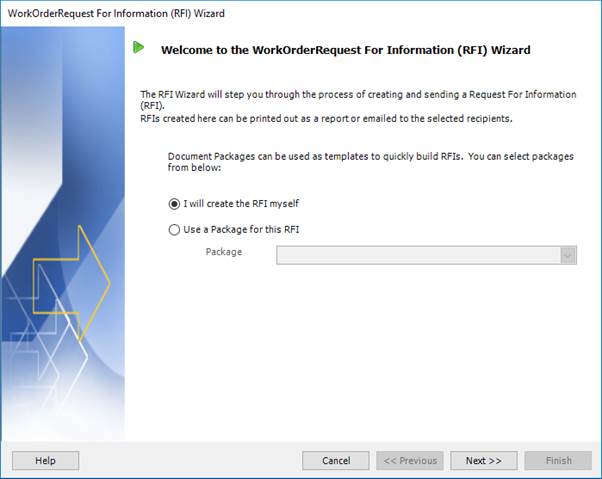

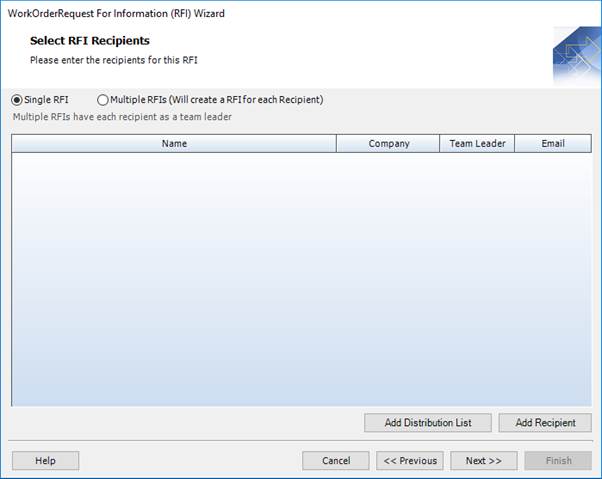

Requests for information (RFI)

Welcome to STRUMIS

Hello and welcome to STRUMIS!

STRUMIS is an information management system that has been designed specifically for the steel fabrication industry. It provides management access to the information that is produced at every stage of a steelwork contract, from tendering, through procurement to manufacturing and delivery to site.

Several types of licence are available, depending on your requirements. They allow you to access one or more of these modules: the main management information system, BIM Review (this is STRUMIS software that allows you to view and manage building information models and data), the STRUMIS estimating software, the STRUMIS planning software, and a no-nonsense interface for workstation operators. Please note that BIM Review is not covered in this documentation.

Chapter 1

Getting started with STRUMIS

What's in this chapter?

Log in to STRUMIS

Find your way around

Work with forms

Work with grids

Work with records

Create a record

Find and edit an existing record

Add notes to a record

Define custom fields for a record

Attach external documents to a record

View basic information about a record

Delete a record

Work with reports

What's next?

Log in to STRUMIS

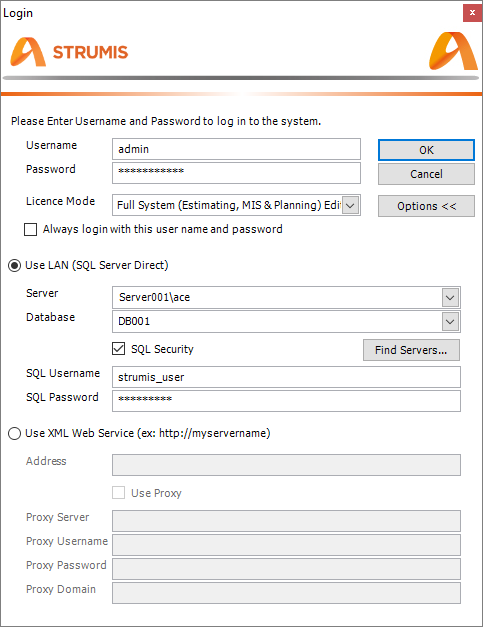

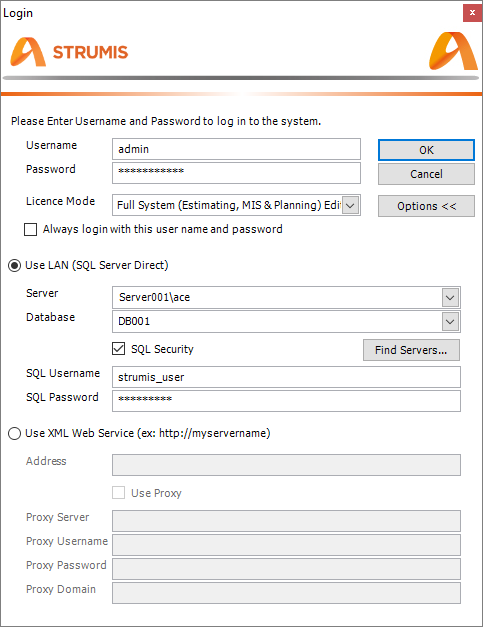

Use the following instructions to log into STRUMIS:

1. To start STRUMIS, go through your Windows menu system or click the STRUMIS icon  .

.

The Login screen is displayed:

(The full login screen is shown below. Click the Options button to display or hide the extra fields.)

2. Type in your username and password and check that the licence mode is correct.

3. Click OK.

The STRUMIS software is launched.

Find your way around

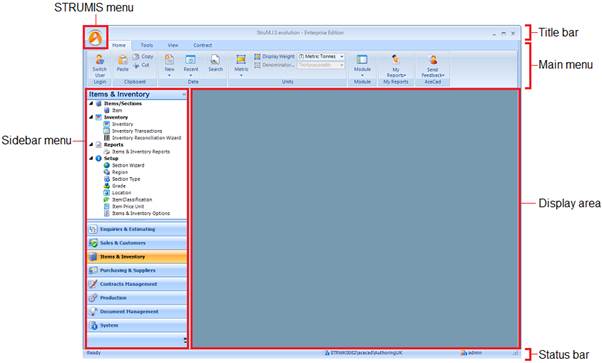

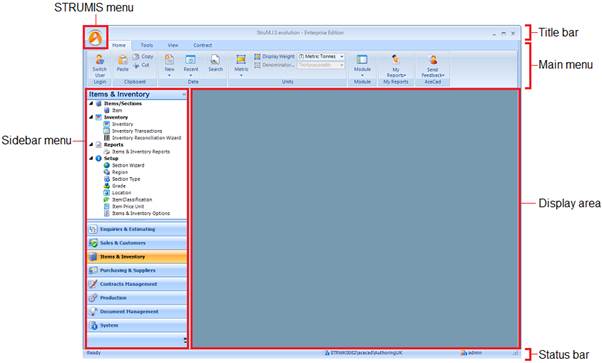

The illustration below shows the main STRUMIS screen. Each of the labelled items is described in detail below.

Title bar

The title bar tells you which edition of STRUMIS you are running and has the standard controls to minimise, maximise and close the screen.

STRUMIS menu

When you click the STRUMIS logo, the following menu is displayed:

The available options are listed in the table below:

|

Option

|

Description

|

|

New

|

Allows you to create new records.

|

|

Save

|

Saves the active open record.

|

|

Import and Export

|

Opens the Import and Export Wizard, which allows you to import files into, or export files from STRUMIS.

|

|

Close

|

Closes the active open record.

|

|

Close All

|

Closes all records.

|

|

Print

|

Saves a screen capture of the active open form to a PDF file.

|

|

Switch User

|

Restarts STRUMIS so that you can log in as a different user.

|

|

About

|

Click this button to:

§ View STRUMIS contact details

§ View your licence details and a list of software versions that you have installed (with access to release notes)

§ Upgrade or activate your licence

|

|

Exit STRUMIS

|

Click this button to close the STRUMIS software.

|

Main menu

There are four tabs on the main menu; Home, Tools, View, and Contract. More detail is given in the tables below:

Home

|

Option

|

Description

|

|

Login

|

The Switch User option restarts STRUMIS so that you can log in as a different user.

|

|

Clipboard

|

Use these options to cut, copy and paste to the clipboard.

|

|

Data

|

§ New

Allows you to create new records.

§ Recent

List the records that you recently accessed.

§ Search

When you choose this option, the General Search form is displayed, allowing you to search for records.

See Find and edit an existing record.

|

|

Units

|

Select the units for use throughout the system. The options are:

§ Metric

§ Imperial

If you select Imperial units, you can also choose a denominator to specify the granularity that you want to be displayed throughout the system. The options are a half, a quarter, an eighth, a sixteen or a thirty-secondth of an inch.

§ Imperial decimal inch

You can also select weight units.

|

|

Module

|

Click this button to display a particular module in the sidebar menu.

|

|

My Reports

|

Click this button to list custom reports by module.

|

|

AceCad

|

Click this button to send an email to STRUMIS support.

|

Tools

|

Option

|

Description

|

|

Data Tools

|

The Data Tools options allows you to:

§ Run the Setup Wizard

§ Backup your SQL database

§ Install a hotfix

§ Run the Import and Export Wizard

|

|

Local Data

|

The Local Data options allow you to:

§ Reset grid layouts to factory settings

§ Refresh the data in drop-down lists (combos)

|

View

|

Option

|

Description

|

|

View

|

The View option allows you to:

§ Toggle the sidebar menu on and off.

§ Toggle the System Navigation screen on and off

|

|

CAD/CAM Viewers

|

This option allows you to view model data using one of the following viewers:

§ BIM Review viewer

§ StruCNC CAM viewer

§ Drawing viewer

|

|

Window

|

The Window option allows you to:

§ Display the welcome screen and videos

§ Configure the display area to show tabbed or non-tabbed windows

§ Launch the on-line help system

§ Display the start page

|

Contract

The options on the Contract Ribbon are very useful when you are carrying out a lot of work on one particular contract. You can specify the contract on which you are working, and then use the buttons along the Contract Ribbon to access various aspects of work particular to the selected contract. For example, if you are working with a contract called C-0100, select it from the Contract drop-down list. If you want to view the detailed listing for C-0100, simply click the Detailed Listing button; you do not have to go through the menu system or search forms.

You can also update contract information from the database (Refresh Contract Information) or create a new contract.

Sidebar menu

Click a module in the sidebar menu to display a list of associated tasks and records in the upper half of the sidebar menu.

Display area

When you select a menu option that requires a form, the form is displayed here.

Status bar

Shows the status of the STRUMIS system, the database that you are using, and the user that is currently logged in.

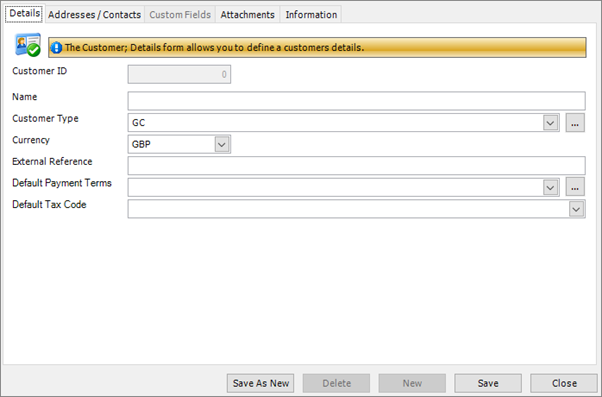

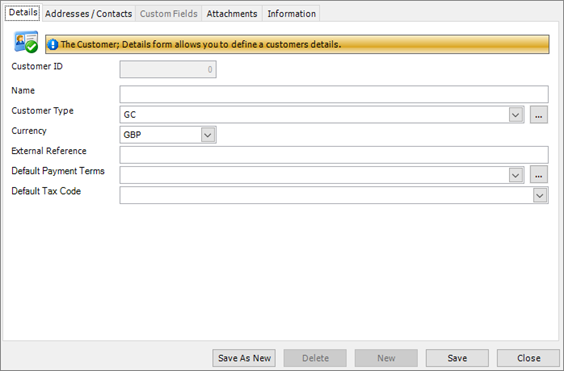

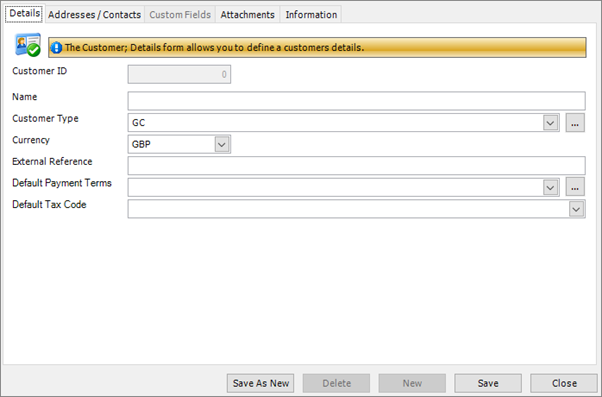

Work with forms

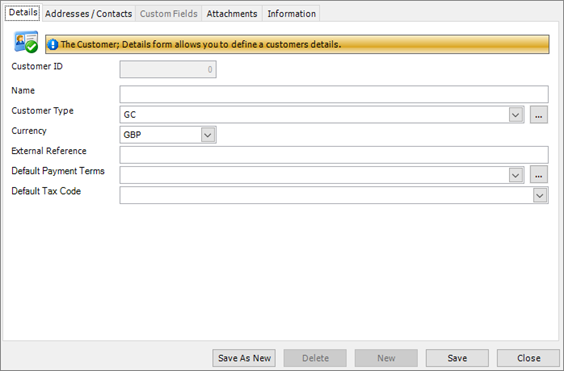

The term form is used to refer to the screen on which a STRUMIS record is displayed. Examples are the Customer form, the Purchase Order form and the Production Workstation form. The illustration below shows you what a simple form looks like. It is the Customer - Details form.

Forms have core features that are common through the system. They are fields, grids and buttons.

Fields

You will find text, numeric, date, drop-down list, and check box type fields in the STRUMIS system. They are frequently displayed on tabs or in smart filters (similar to tabs). Fields, tabs and smart filters are described on a case-by-case basis throughout this documentation.

Grids

Many STRUMIS forms contain grids with sophisticated control mechanisms.

See Work with grids.

Buttons

On each form, you will find one or more of the buttons in the following table:

|

Button

|

Description

|

|

Actions

|

Lists the various operations that you can do to the record.

|

|

Grid Options

|

See Work with grids

|

|

Save

|

Saves the record.

|

|

Save As New

|

If you are creating more than one record of the same type with similar details, use the Save As New button.

When you have completed and saved the first record, you can simply change the name and click Save As New to save the same details under the new name.

|

|

Delete

|

Deletes the record from the database. You cannot retrieve a record when it has been deleted.

|

|

Close

|

Closes the record.

|

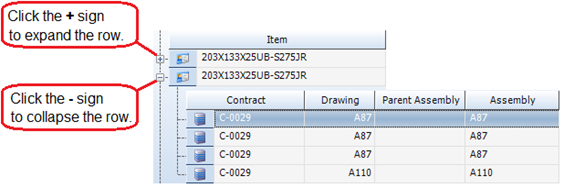

Work with grids

Grids feature on many STRUMIS forms. They have their own controls, which are listed when you click the Grid Options button. Before you begin to set grid options, however, you can:

§ Click a column header to sort information into alphabetic or numeric order. Click it again to sort the information into reverse alphabetic or numeric order.

§ Rearrange the columns in the grid. To do this, click, hold and drag a column header to a different location.

Grid Options

The following options are available when you click the Grid Options button.

§ Select All

Selects all of the rows in the grid. You can also click a row and press Ctrl A to select all of the rows.

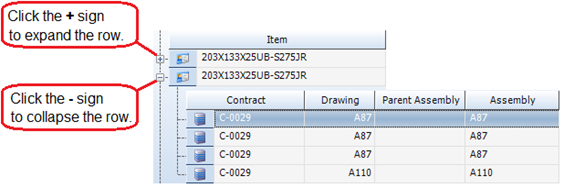

§ Expand All and Collapse All

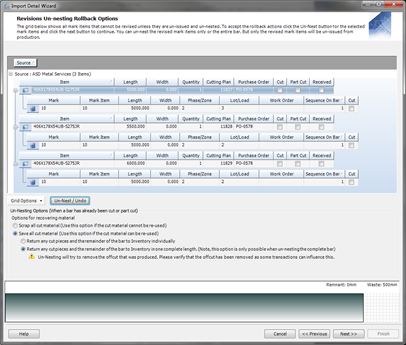

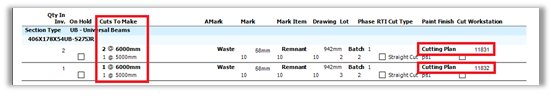

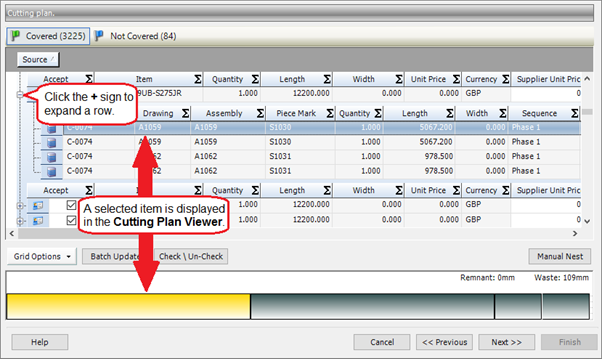

Some grids contain rows that you can expand to display extra information (click the + sign at the beginning of the row) or collapse to hide the information (click the - sign at the beginning of the row). Here's an example from the Cutting Plan Viewer:

To expand or collapse all of the rows in this type of grid, use the Expand All or Collapse All options respectively.

§ Print Preview

This option displays the Print Preview form, where you can check and then print the grid:

§ Export to Excel

Opens Microsoft Excel and exports the information in the grid.

§ Copy to Clipboard

Copies the information in the grid to the clipboard. You can then paste the information into a third-party software package.

§ Autofit Columns

Increases or decreases the width of the columns so that the grid fits into the window.

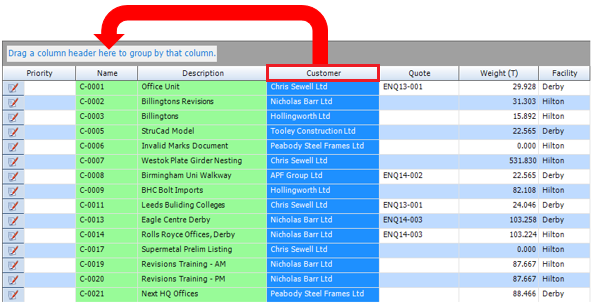

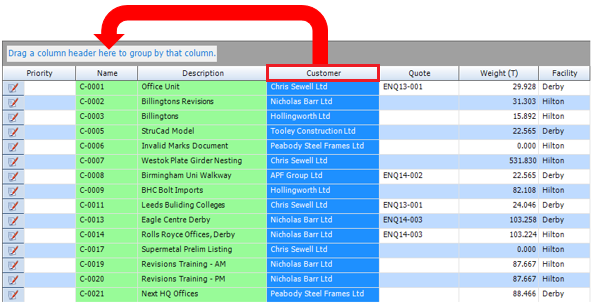

§ Group By

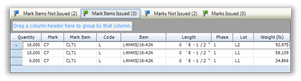

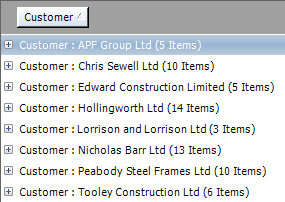

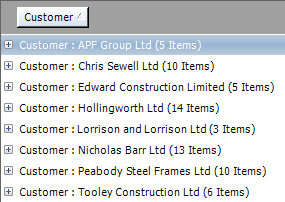

This option allows you to group the information in the grid by a specific column. When you select the option, a message, Drag a column header here to group by that column, is displayed at the top of the grid. The example below shows how to group contracts by customer name. Drag the Customer column header to the grey area as shown:

You can see that the grid now lists the customers and allows you to expand each row to display the associated contracts.

To display the information in its original format, simply drag the column header from the grey area back to the grid.

§ Filter Columns

See Filter columns below.

§ Row Summaries

This option allows you to add various summaries to the bottom of a column. The range of summary types that are available depends on the column; for example, Average and Sum are only available when being applied to columns containing numeric values.

When you select this option, a summary icon is added to the column headers in the grid. To select a summary:

a. Click the icon.

The Summaries form is displayed.

b. Select one or more types of summary and click OK.

c. The summary is added to the bottom of the column.

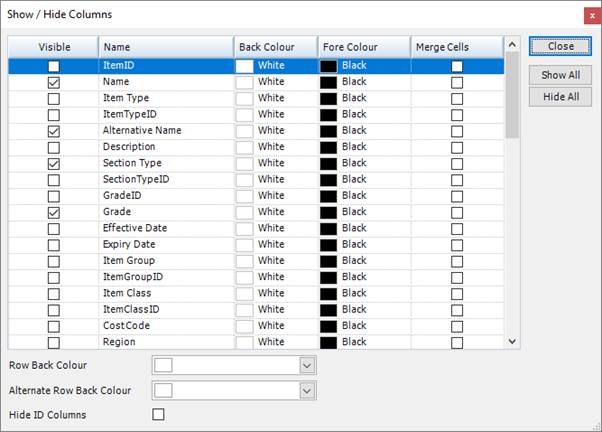

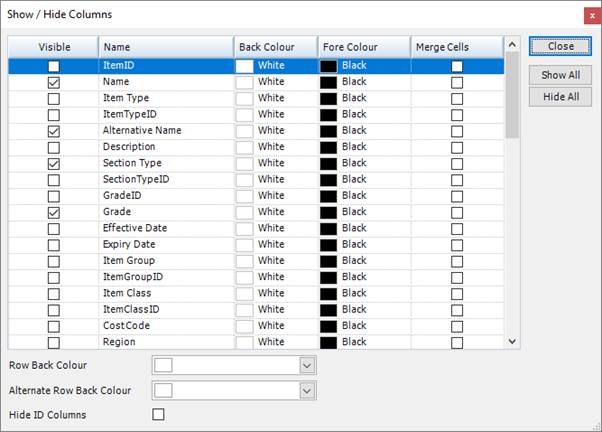

§ Show/Hide Columns

See Show/Hide columns below.

§ Reset Grid Layout

Resets the grid layout to the factory settings.

§ Reset Sort Order

Resets the sort order of the grid to the factory settings.

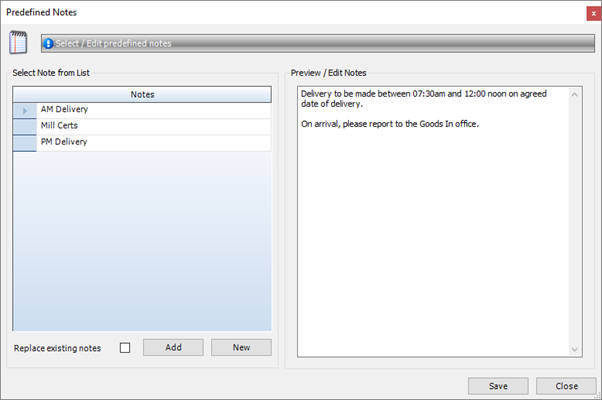

Filter columns

STRUMIS provides a sophisticated facility that allows you to filter grids so that they display the exact information that you require. For example, on the Contracts Search form, you could list the jobs that you won this month, by building type, tonnage and sales area.

The available filter options are described below.

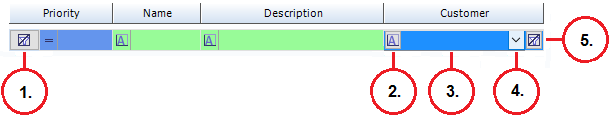

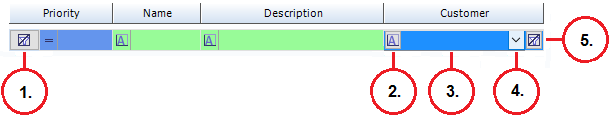

When you select the Filter Columns grid option, an extra row is displayed at the top of the grid. The various utilities in this row allow you to display very specific information in the grid by filtering the information to show only the details in which you are interested.

The example below shows the extra row for the Contracts Search form.

The following table tells you about the numbered features in the illustration:

|

Number

|

Description

|

|

1.

|

This button, at the beginning of the row, clears all filter criteria for the grid.

|

|

2. and 3.

|

These features are available for every column. They are displayed when you click the filter row for a particular column

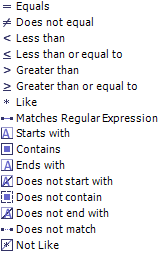

Click the button (feature number 2.) to display the filter operators; they are:

Select an operator and then type in an operand (at feature number 3.). These terms may be unfamiliar to you, so let's take a look at an example.

Imagine that you had a list of contracts for a variety of customers. You want to review the contracts for Peabody Steel Fames Ltd. On the Contracts Search form, enable the Filter Columns grid option. In the Customer column, select the Contains operator and type in the operand Peabody. The grid is filtered as you type. It now shows only the contracts for customers with Peabody in their name.

|

|

4.

|

This button is available for every column. It is displayed when you click the filter row for a particular column.

When no filters have been applied to the column, the drop-down list contains every unique record in the column along with the following options.

§ Custom

You can define a sophisticated custom filter using the operator/operand information given above for features 2. and 3.

§ Blanks

You can filter the information to show only records that have blanks for this column.

§ NonBlanks

You can filter the information to show only records that have non-blanks for this column.

If you have applied filters, the drop-down list shows only records that match the filter criteria.

Select an option from the drop down list.

|

|

5.

|

This button is available for every column. It is displayed when you click the filter row for a particular column. Click the button to clear the filter criteria for the column.

|

Show or hide columns

Throughout the system, the grids typically show a subset of the information that is available. When you select the Show/Hide Columns grid option, the Show/Hide Columns form is displayed. It allows you to choose the columns that you want to see in the grid and colour code them for easy viewing.

Work with records

There are many types of record in STRUMIS. For example, a customer record stores the name and contact details for a customer, and a contract record stores details of a job that you are undertaking for a customer.

Create, edit and delete records

Usually, you create, edit and delete STRUMIS records using standard methods. These are listed below. Instructions for dealing with records that deviate from the standard, are included in the relevant sections throughout this documentation.

§ Create a record

§ Find and edit an existing record

§ Delete a record

Common elements

Different types of record often have common elements. Specifically, you can:

§ Add notes to most records

This is a simple process and is described in Add notes to a record.

§ Define your own custom fields for many records

Although this is a simple process, the custom fields that you define are used for the record type rather than for an individual record. For example, if you define a custom field for a specific purchase order, it appears in all purchase order records. For this reason, adding custom fields requires careful consideration and is usually carried out by an experienced STRUMIS user, a member of your IT staff, or your STRUMIS administrator. It is described in Define custom fields for a record.

§ Attach external documents to most records

This is a simple process and is described in Attach external documents to a record.

§ View basic information for all records

This is a simple process and is described in View basic information about a record.

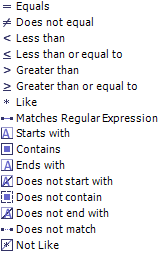

Create a record

There are many different types of record in the STRUMIS system and you can create most of them using the following instructions. Other methods are available; they are listed in the notes below.

1. Click a module in the sidebar menu.

The menu items for the module are listed at the top of the sidebar menu.

2. Click the type of record that you want to create.

The search form for the record type is displayed.

3. Click the New button in the top right-hand corner of the search form.

The form for the record type is displayed.

4. Fill in the necessary information and click Save.

A new record is created.

|

|

There are other ways to create a record. They are listed below:

§ If you are creating more than one record of the same type with similar details, use the Save As New button.

When you have completed and saved the first record, you can simply change the name and click Save As New to save the same details under the new name.

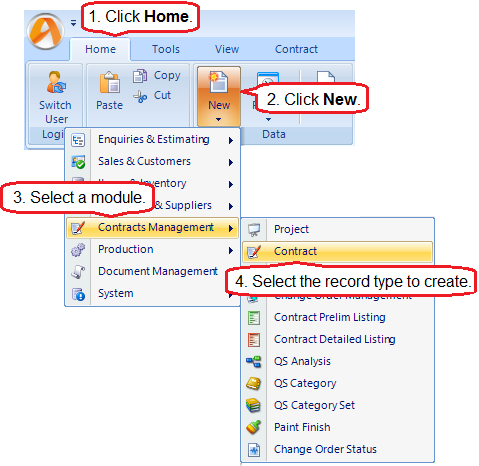

§ From the main menu:

Click Home, then New. Select a module and the type of record that you want to create.

The form for the record type is displayed and you can fill in the necessary information and click Save.

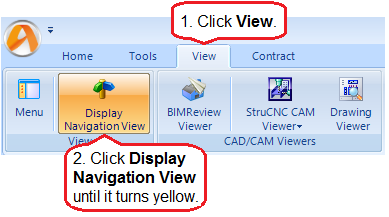

§ From the System Navigation form:

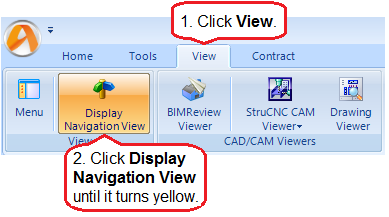

First, make sure that system navigation is switched on. To do this, in the main menu, click View, then click Display Navigation View until the button turns yellow and the System Navigation form is displayed.

Now, when you click a module in the sidebar menu, the System Navigation form shows a flow diagram of the major steps required for the module. Some of the steps are to create new records. Click a box to create the record.

|

Find and edit an existing record

The following instructions tell you how to find and open a record for editing. If you carry out the instructions and there are still too many records to look through, apply a filter to the grid to narrow down the number of records listed. See Work with grids.

1. Click a module in the sidebar menu.

The menu items for the module are listed at the top of the sidebar menu.

2. Click the type of record for which you want to search.

The search form for the record type is displayed and all of the records of the selected type are listed.

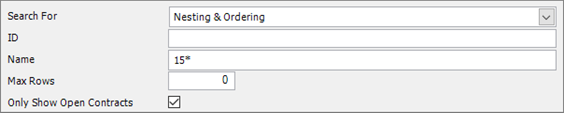

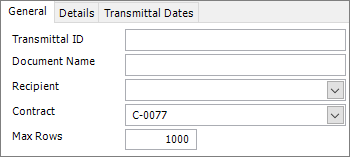

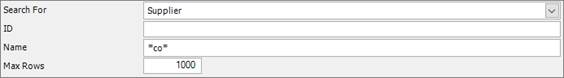

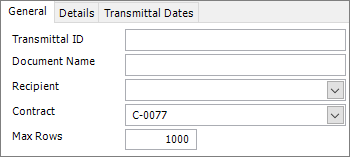

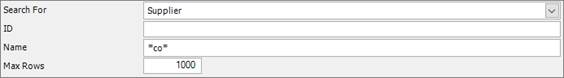

3. Type your search criteria into the fields at the top of the form.

The example below shows the search criteria for a supplier record; you can search for the name of the supplier company. The search returns a list of suppliers with the term *co* somewhere in their name.

4. Set the Max Rows and Only Show Open Records parameters.

The maximum number of matching records is typically set to 1000. If there are more than that, you should consider narrowing your search.

As you use the STRUMIS system, you will open new records and close old ones. To limit your search to open records, select the Only Show Open Records check box.

5. Click Search.

Records matching your search criteria are listed.

6. Double-click a record in the list to edit it.

The form for the selected record is displayed.

7. Fill in the necessary information and click Save.

Your changes are saved and the form is closed.

|

|

§ If you leave the search fields blank, all records for the module are listed.

§ Click Clear to reset the search criteria.

§ Search criteria are not case sensitive.

§ You can use the following characters in the search fields:

*

Use the asterisk as a wildcard. If, for example, you wanted to show every member with a grade of –S275, type in *-S275. Every record in the module that ends with -S275 is displayed.

_

Use an underscore to represent any character; for example, _275 lists all records in the module with four characters that end with 275.

%

Use a percent sign to match any character that occurs multiple consecutive times. For example, C%per* would find both Cooper Steel Construction and Caper Fabrication Ltd.

[ ]

Use square brackets to denote a character range; for example, *U[B-C]* lists all UB codes and UC codes.

|

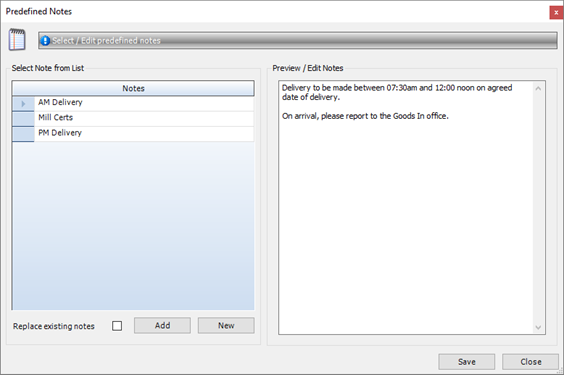

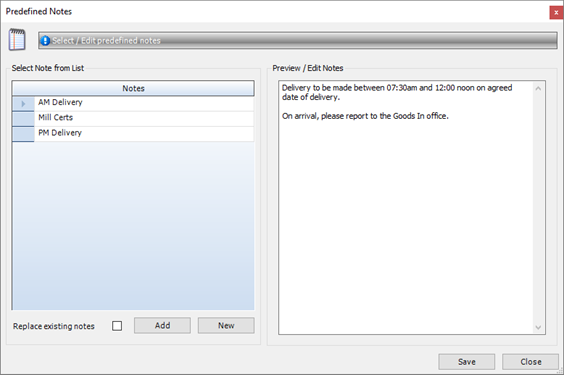

Add notes to a record

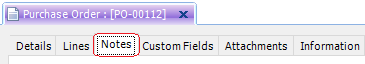

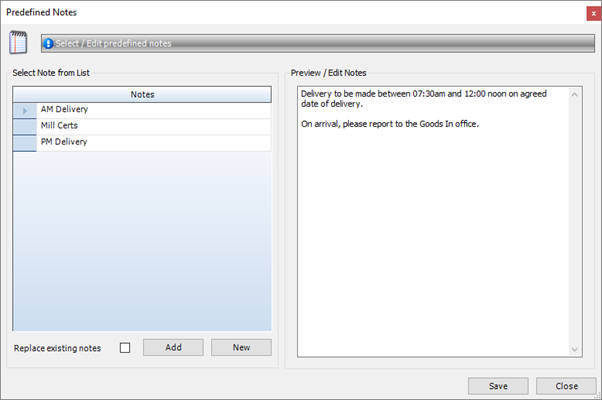

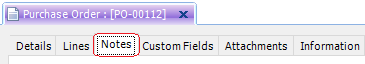

You can add notes to most records in the STRUMIS system. Typically, you can type free text directly into the note field, or you can add one or more predefined notes. The most common place to add notes is on a record's Notes tab. The example below shows the Notes tab for a purchase order record.

Predefined notes

To access predefined notes

Click the Predefined Notes button. (If you are adding a predefined note somewhere other than on a Notes tab, this button may have an alternative label, but its purpose will be obvious.)

The Predefined Notes form is displayed.

To define a note

On the Predefined Notes form:

1. Click the New button.

The New Note form is displayed.

2. Specify a name for the new note and click OK.

The name is added to the list on the Predefined Notes form.

3. Select the name in the list and type the note text into the Preview/Edit Notes area.

4. Click Save.

To add a predefined note to a record

On the Predefined Notes form:

1. Select a note from the list.

If you want to append the note to other that are already present on the Notes tab (or other location), clear the Replace existing notes check box.

If you want to use the selected note to replace other notes that exist on the Notes tab (or other location), select the Replace existing note check box.

2. Click Add.

The note is added

3. When you have added the required notes, click Close.

Define custom fields for a record

The data fields in STRUMIS cover most aspects of steel fabrication, but there may be instances when you need to collect data and there is no suitable field in which to store it within the STRUMIS system. You can define custom fields to accommodate such cases. Although this is a simple process, the custom fields that you define are used for the record type rather than for an individual record. For example, if you define a custom field for a specific purchase order, it appears in all purchase order records. For this reason, adding custom fields requires careful consideration and is usually carried out by an experienced STRUMIS user, a member of your IT staff, or your STRUMIS administrator.

Use the following instructions to define custom fields:

1. Create or open a record.

See Create a record or Find and edit an existing record.

2. Click the Custom Fields tab.

It looks like this:

Any previously defined custom fields are listed here.

3. Click the Define... button.

The User Field Define form is displayed.

4. Scroll down the list and you will see that you can define up to 22 text fields, 8 numeric fields, 6 data fields and 4 check box fields.

5. In the Field Name column, next to the type of field that you want to define, type in a field name. Select the Active check box to make your new custom field live, and select the Mandatory check box if you want to force users to populate the field.

6. When you have added the custom fields that you need, click OK.

The custom fields are listed on the Custom Fields tab for all records of this type.

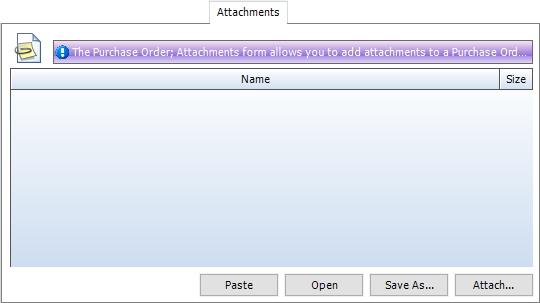

Attach external documents to a record

Use the following instructions to attach external documents to a STRUMIS record:

1. Create or open a record.

See Create a record or Find and edit an existing record.

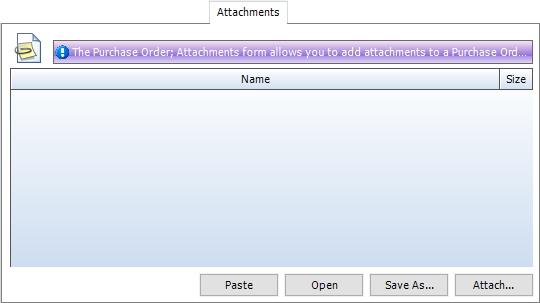

2. Click the Attachments tab.

It looks like this:

3. Click the Attach button and browse for the external document.

The document that you select is attached to the record and listed in the grid.

|

|

§ You can attach a document to a record using standard copy and paste utilities.

Copy a document in File Explorer, then click the Paste button here on the Attachments tab.

§ You can open an attached document.

Select the document in the grid and click the Open button.

§ You can save an attached document to a location in File Explorer.

Select the document in the grid, click the Save As... button, and browse for the location.

|

View basic information about a record

Use the following instructions to view basic information for a record.

1. Create or open a record.

See Create a record or Find and edit an existing record.

2. Click the Information tab.

It looks like this:

More information is available for some record types.

Delete a record

The following instructions tell you how to delete a record.

1. Search for the record.

See Find and edit an existing record if you need help with this.

2. On the Search form, select the record that you want to delete.

3. Press the Delete key on your keyboard.

You are prompted to confirm the deletion.

4. Click Yes to delete the record.

|

|

This operation deletes the record from the database. You cannot undo it.

|

|

|

You cannot delete a record if it used elsewhere in the system.

|

Work with reports

STRUMIS reports are categorised as follows:

§ Standard reports

These are supplied with the system.

Please refer to the online help system for a list of standard STRUMIS reports.

§ User-defined reports

These are reports that you create specifically for use in your business. Please contact STRUMIS Support for further information.

§ Batch reports

There are many places in STRUMIS where you can print a report. The most commonly used are:

§ From the sidebar menu

Each module has a reports section, which you can access from the sidebar menu. For example:

To access reports that are related to the inventory, go to Items & Inventory > Items & Inventory Reports.

To access reports that are related to purchase orders, go to Purchasing & Suppliers > Purchasing & Suppliers Reports.

You can print reports here (select a report and click the Run button) and you can add reports to a list of favourites that you access from the Contract Ribbon.

§ From the Contract Ribbon

There are two reporting options on the Contract Ribbon. The first, Contract Reports, allows you to view and print reports that contain information related to the default contract. The second, My Contract Reports, allows you to view and print your favourite reports.

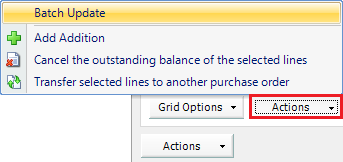

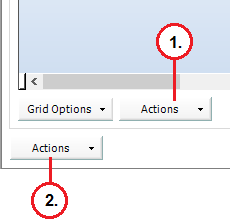

§ From an Actions button

Actions buttons are available on many forms throughout the system. A Print or Report option allows you to print reports related to the form.

The following sections tell you how to add reports to your list of favourites, and how to print a report.

Add a report to your list of favourites

The following instructions use item and inventory reports as an example, but they apply to all reports.

1. From the sidebar menu, go to Items & Inventory > Items & Inventory Reports.

The Items & Inventory Reports - Details form is displayed.

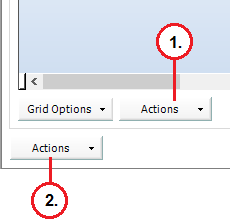

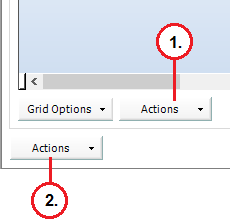

2. Select a report in the list and click Actions (button) > Add To My Reports.

The selected report is added to your favourites.

You can remove reports from your favourites in a similar way by using the Remove From My Reports option.

To access your favourite reports, click the My Contract Reports button on the Contract Ribbon.

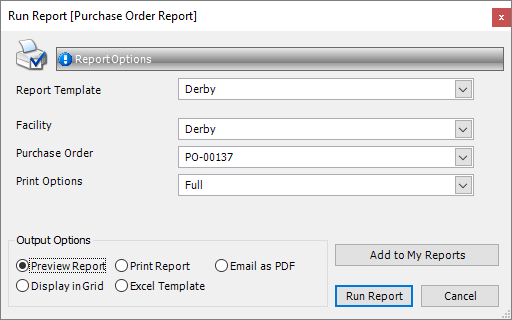

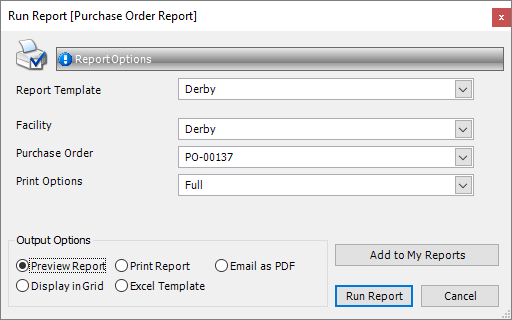

Print a report

When you print a report using one of the methods mentioned above, the Run Report form is displayed. The fields on the form differ according to the report that you run, but here is an example for a Purchase Order Report.

Specify the information for the report and select an output option.

|

Output option

|

Description

|

|

Preview Report

|

Displays the report on the screen. See Preview_a_report, below.

|

|

Print Report

|

Automatically sends the report to the printer without preview.

|

|

Email As PDF

|

Opens your default email system and attaches the report as a PDF file.

|

|

Display In Grid

|

Sends the information in the report to a grid on a new tab. You can customise the grid (see Work with grids) and export the information to Microsoft Excel. The grid report layouts are saved so that you can run the same report at a later date.

|

|

Excel Template

|

|

Now, click the Run Report button.

Preview a report

If you elect to preview a report, the Report Preview form is displayed. It shows the report and gives you the following options:

|

Option

|

Description

|

|

|

Refresh

Refreshes the preview after you make changes to the data contained in the report.

|

|

|

Email

Opens you default email system (for example, Microsoft Outlook), attaches the report, and allows you to enter a recipient and a message before sending.

|

|

|

Add To/Remove From My Reports

|

|

|

Print

Prints the report to your default printer.

|

|

|

Copy

Copies the report to the clipboard. You can then paste the report into a third-party software package such as Microsoft Excel.

|

|

|

Single Page View

|

|

|

Multiple Page View

When you click this button, you can select the number of pages of the report that you want to display on the preview form.

|

|

|

Continuous scroll

This is a toggle that allows you to either scroll up and down a single page, or to scroll continuously through the document.

|

|

|

Zoom

The zoom controls allow you to zoom in and out, or to type in the zoom level that you require.

|

|

|

Page scroll

Use these controls to go to the next page, previous page, or to type in the page that you want to view.

|

|

|

Backward and Forward

You may have viewed page 1 of the report, then page 6, then page 10. These buttons allow you to step back and forth between the pages that you have viewed.

|

|

|

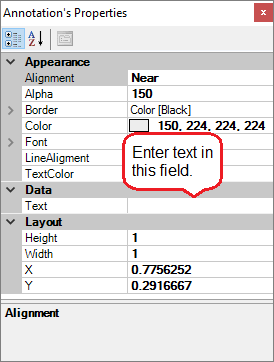

Annotation

You can annotate a report. Use the following instructions:

3. Click the Annotation icon

A menu is displayed.

4. Click-and-drag a shape from the menu onto the report.

5. Right-click the shape.

You have the option to view the properties of the shape, or to delete it.

6. Select Properties.

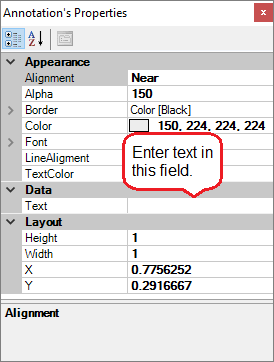

The Annotation Properties form is displayed.

7. Edit the shape properties as required. For the text, arrow, balloon and line annotations, you can enter notes in the Text field.

8. Close the form.

|

|

|

Use this button to export the report to one of the following formats:

Excel

PDF (Acrobat)

HTML (Web Page)

RTF (Word)

Tiff (Image)

Text (CSV)

Text (Tab)

Email As PDF

|

What's next?

Now that you have logged in and had a first look around STRUMIS, you can begin to add data. Creating a customer is a good place to start.

Chapter 2

What's in this chapter?

About customers

Create a customer record

Import customer records

Customer reports

Find and edit a customer record

Customer reports

What's next?

Fields and buttons

About customers

When a potential customer contacts you for information such as a quote or a detailed estimate, you can record their name and contact details in STRUMIS. These details can be amended at any time and are used for any future dealings with the customer. You can choose to record one customer at a time, or you can import customer details from Microsoft Outlook or a csv file by using the Setup Wizard.

Access

To access customer records, from the sidebar menu, go to Sales & Customers > Customer.

When you create or edit a customer record, you will use the Customer form.

Create a customer record

The following instructions tell you how to create a customer record.

1. Go to Sales & Customers > Customer.

A list of customers is displayed.

2. Click New.

The Customer form is displayed.

It has the following tabs:

§ Details

Specify basic information for the customer. This includes their company name, type and payment terms.

See Customer - Details for a full list of the fields and buttons on this tab.

§ Addresses/Contacts

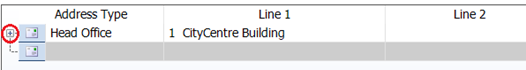

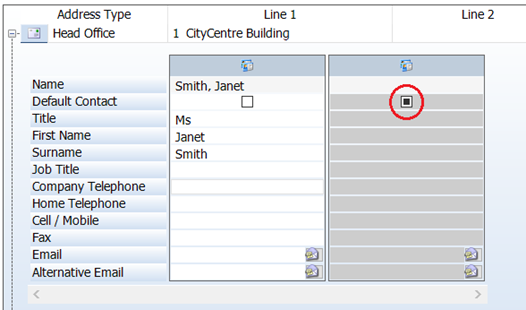

Specify one or more contacts and addresses for the customer.

See Customer - Addresses for a full list of the fields and buttons on this tab.

§ Custom Fields

If you need to collect data that is relevant to this type of record, but there are no appropriate fields, use this form to define your own custom fields.

See Define custom fields for a record for a full list of the fields and buttons on this tab.

§ Attachments

Use this form to attach external documents to a STRUMIS record.

See Attach external documents to a record for a full list of the fields and buttons on this tab.

§ Information

Use this form to view the creation date of the record, the date when it was last updated, and the users who made the changes.

See View basic information about a record for a full list of the fields and buttons on this tab.

3. Add basic customer information in the Details tab.

4. Add one or more addresses (for example a delivery address and a billing address) and contacts in the Addresses/Contacts tab.

To add addresses and contacts:

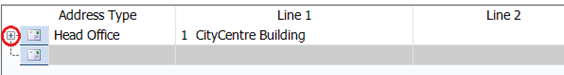

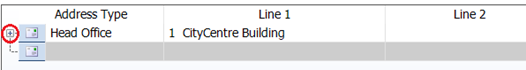

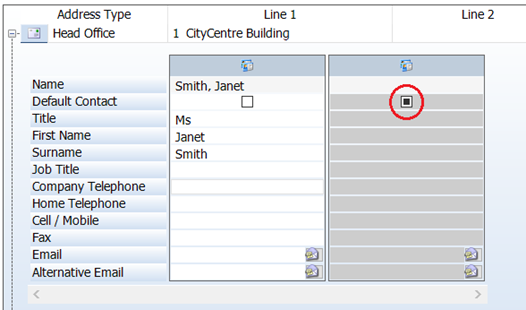

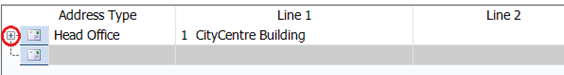

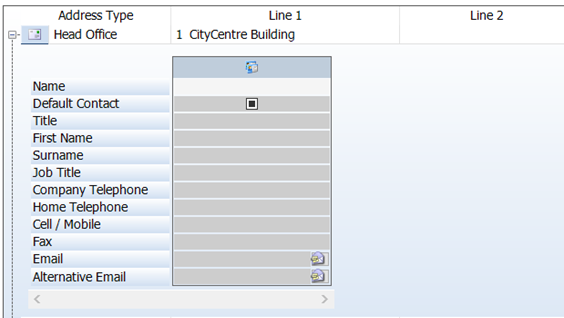

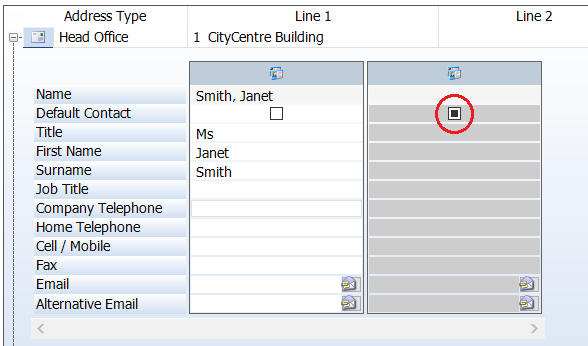

a. Type into the fields Address Type, Line 1, Line 2 and so on. When you begin to type, a plus sign (+) is displayed at the beginning of the address line (circled in red below).

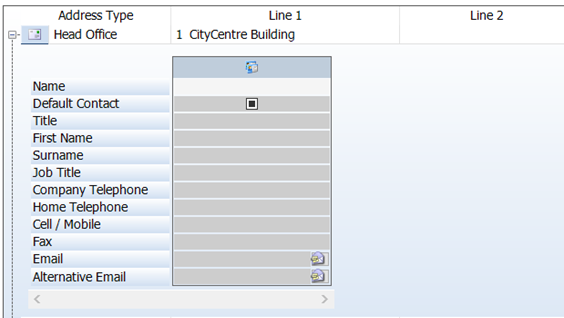

b. Click the + to display the contact information fields.

c. Type in your contact information.

Press F1 if you need help.

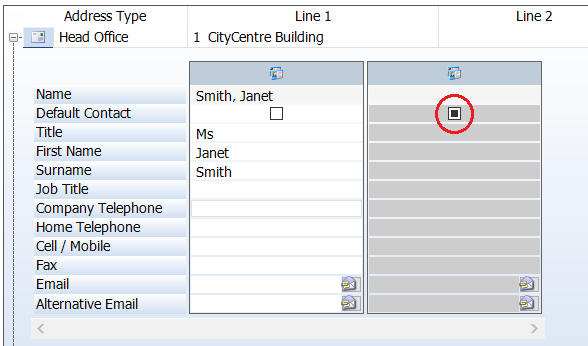

d. To add multiple contacts for this address, click the button circled in red below.

e. Click the Default Contact check box to indicate the default contact.

5. Click Save.

|

|

If you are creating multiple customer records, use the Save As New button When you have completed and saved the first set of customer details, you can simply change the customer name and click Save As New to save the same details under the new customer name.

|

Import customer records

You can import customer records into STRUMIS. To do this, use the Setup Wizard (go to System > Setup Wizard), which leads you through the process.

Customer reports

You can access reports from the sidebar menu. Go to Sales & Customers > Sales & Customers Reports.

See also:

Work with reports

List of reports

Find and edit a customer record

1. Open the Search form from the sidebar menu.

To do this, go to Sales & Customers > Customer.

2. Enter search criteria and click the Search button.

Records that match your search criteria are listed.

3. Double-click a record to edit it.

For complete information, see Find and edit an existing record.

Customer reports

You can access reports from the sidebar menu. Go to Sales & Customers > Sales & Customers Reports.

See also:

Work with reports

List of reports

What's next?

When you have set up a customer record, you can move on to create a quote (enquiry) or an estimate for the customer.

See About Enquiries and About estimates

If you have already won the order, you can go on to create a contract for your new customer.

See About contracts

Fields and buttons

Customer - Details

Use this form to enter basic customer details.

Fields

|

Field

|

Description

|

|

Customer ID

|

Populated automatically from the fields below.

|

|

Name

|

Type in or edit the name of the customer.

|

|

Customer Type

|

Do one of the following:

§ Select a customer type (for example, architect or engineer) from the drop-down list.

§ Add and select a new customer type in the look-up dialog, which you can access by clicking the ellipsis (...).

|

|

Currency

|

Select a currency from the drop-down list. This is the currency that your customer uses for business transactions.

|

|

External Reference

|

This is a free text field where you can store an extra reference number for your customer, for example, their reference number from your accounting system.

|

|

Default Payment Terms

|

Select payment terms from the drop-down list. A typical example is Net 90, which means that payment is required 90 days after the invoice date.

|

|

Default Tax Code

|

Choose a tax code from the drop-down list. For example, if your customer is based in the USA, tax codes can be associated with a state sales tax, which is automatically added to the invoice. In the UK, you can use this field to add VAT to the invoice.

|

Customer - Addresses

Use this form to add contacts and addresses for a customer.

Address fields

|

Field

|

Description

|

|

Address ID

|

System generated

|

|

Version

|

System generated

|

|

AddressSourceTypeID

|

System generated

|

|

SourceKey

|

System generated

|

|

Address Type

|

Specify the type of address, for example, the head office or billing address.

|

|

Lines 1, 2, 3 and 4

ZIP/Postal Code

Country

|

Type in the address details.

|

Contact fields

|

Field

|

Description

|

|

Contact ID

|

System generated

|

|

Version

|

System generated

|

|

Name

|

System generated

|

|

AddressID

|

System generated

|

|

Default Contact

|

Select this check box to indicate the default contact for this address.

|

|

Title

First Name

Surname

Job Title

Company Telephone

Home Telephone

Cell/Mobile

Fax

|

Type in the contact details.

|

|

Email

Alternative Email

|

Type in an email address. The button at the end of the line opens a blank email where the recipient is populated with this email address.

|

Chapter 3

What's in this chapter?

About enquiries and quotations

Create an enquiry

Set up a parent enquiry

Add customer contacts

Create and print a quotation

Find and edit an enquiry

Enquiry reports

What's next?

Fields and buttons

About enquiries and quotations

When a potential customer requests a quotation, use the Enquiry module to store information about the details of the project, including contacts and key requirements. You can then create a quotation (using boiler plate text if required) and send it to the potential customer.

Access

To access enquiries and quotations, click the Enquiry button on the Contract Ribbon. Alternatively, from the sidebar menu, go to Enquiries & Estimating > Enquiry & Quotation.

When you create or edit an enquiry/quotation, you will use the Enquiry form.

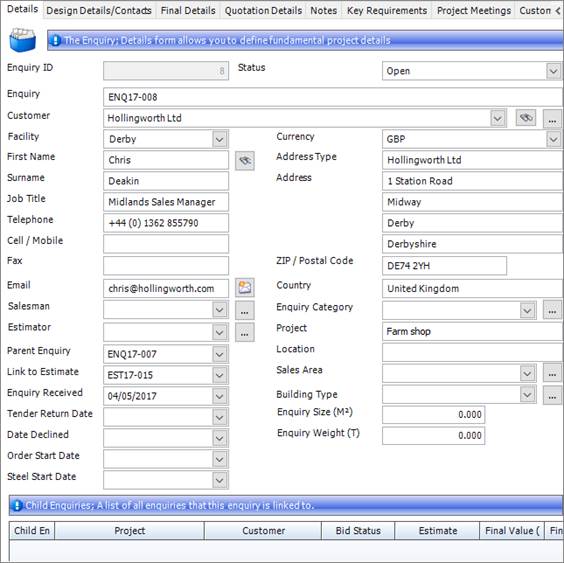

Create an enquiry

The following instructions tell you how to create an enquiry.

1. Go to Enquiries & Estimating >Enquiry.

A list of enquiries is displayed.

2. Click New.

The Enquiry form is displayed.

It has the following tabs:

It has the following tabs:

§ Details

Enter basic details about the enquiry. You can specify the status of the enquiry, customer contact details, links to any associated estimates, and the type of building involved along with details of the area and weight of material required.

See Enquiry - Details for a full list of the fields and buttons on this tab.

§ Design Details/Contacts

Record contact details for the people who are involved in the project. You can also specify the type of work to be carried out and the period during which the design work is to be undertaken.

See Enquiry - Design Details/Contacts for a full list of the fields and buttons on this tab.

§ Final Details

Enter information about the project when the details have been finalised.

See Enquiry - Final Details for a full list of the fields and buttons on this tab.

§ Quotation Details

Specify the text to include the Enquiry Quotation report.

See Enquiry - Quotation Details for a full list of the fields and buttons on this tab.

§ Key Requirements

Record the key requirements for the project These include the scope of the work, materials, certifications, and administration requirements.

See Enquiry - Key Requirements for a full list of the fields and buttons on this tab.

§ Project Meetings

Add notes for up to five project meetings.

See Enquiry - Project Meetings for a full list of the fields and buttons on this tab.

§ Notes

You can add free text notes or predefined notes to this record.

See Add notes to a record for a full list of the fields and buttons on this tab.

§ Custom Fields

If you need to collect data that is relevant to this type of record, but there are no appropriate fields, use this form to define your own custom fields.

See Define custom fields for a record for a full list of the fields and buttons on this tab.

§ Attachments

Use this form to attach external documents to a STRUMIS record.

See Attach external documents to a record for a full list of the fields and buttons on this tab.

§ Information

Use this form to view the creation date of the record, the date when it was last updated, and the users who made the changes.

See View basic information about a record for a full list of the fields and buttons on this tab.

3. Fill in the required information and click Save.

Set up a parent enquiry

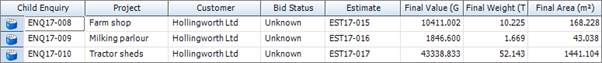

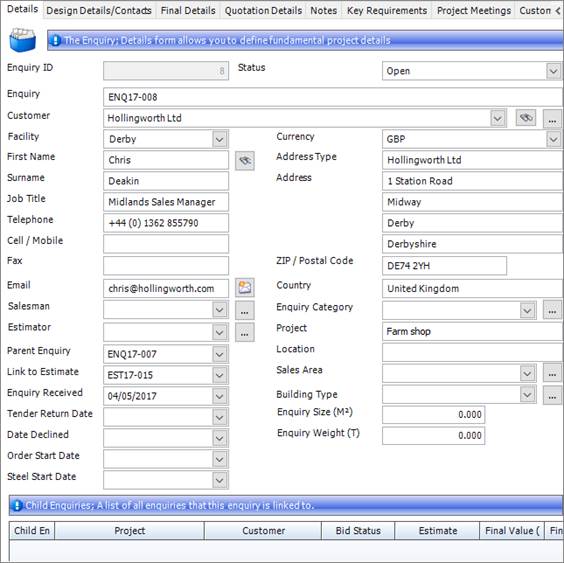

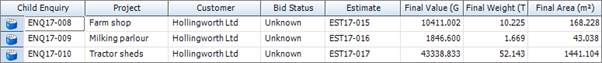

You can build a two-tier enquiry hierarchy where multiple child enquiries are linked to a parent enquiry. You can link an estimate to each of the child enquiries. These are listed in the parent enquiry. The following instructions tell you how to set up the hierarchy.

§ For the parent enquiry:

On the Enquiry - Details form, leave the Parent Enquiry and Link To Estimate fields blank.

§ For each child enquiry:

On the Enquiry - Details form, in the Parent Enquiry field, select the name of the parent that you set up above. In the Link To Estimate field, select an estimate that is associated with this enquiry.

When you return to the parent enquiry, the Parent Enquiry and Link To Estimate fields on the Enquiry - Details form are unavailable and the linked child enquiries and estimates are listed in the grid, as shown below.

Add customer contacts

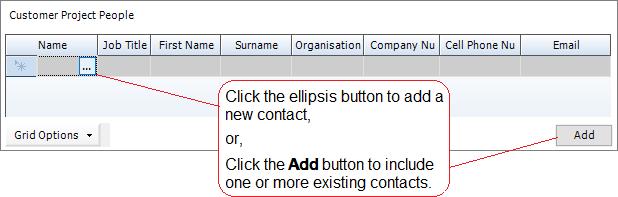

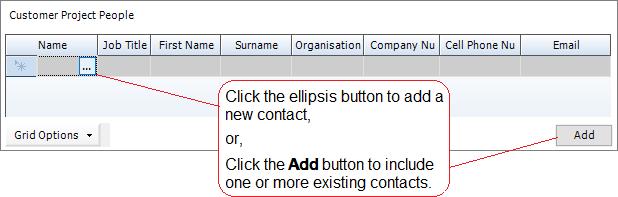

Use the following instructions to add customer contacts to the enquiry. You can add a new contact or include one or more existing contacts.

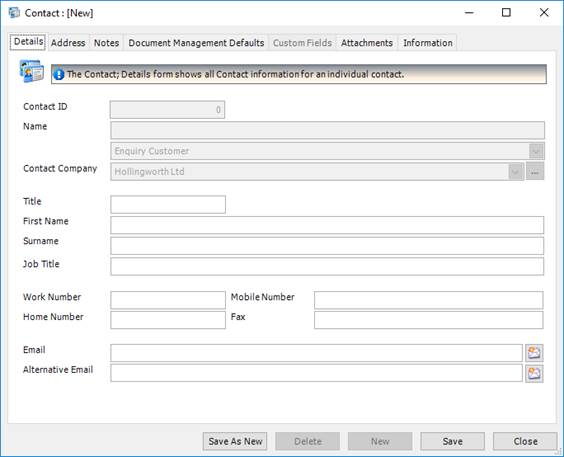

To add a new contact

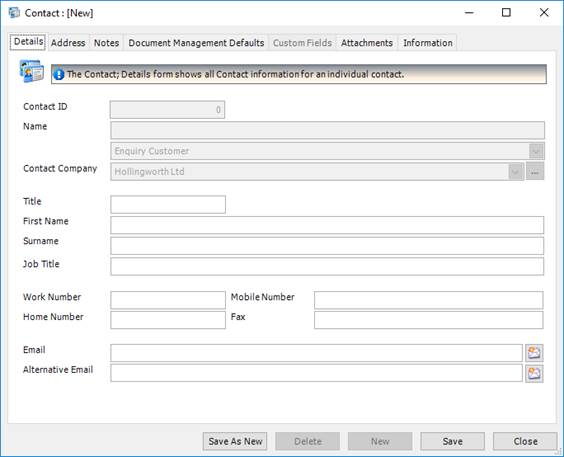

1. On the Enquiry - Design Details/Contacts form, in the Customer Project People grid, click in the Name column, then click the  ellipsis button.

ellipsis button.

The Contact form is displayed.

2. On the Contact - Details form, specify the person's name, job title, telephone numbers and email address and click Save.

3. On the Contact - Address form, specify the person's full address and click Save.

To include multiple existing contacts

1. On the Enquiry - Design Details/Contacts form, click the Add button.

The Contact Search form is displayed. It lists all of the contacts that have been previously defined.

2. Scroll down the list and select the contacts that you want to add to the enquiry.

To do this:

§ Press Ctrl A to select all lines, or

§ Press the Ctrl key and click several non-contiguous lines, or

§ Press the Shift key then click the first and last lines in a range.

3. Click the Add button.

The contacts are added to the Customer Project People grid on the Enquiry - Design Details/Contacts form.

Create and print a quotation

Carry out the following steps to create and print a quotation.

1. Create an enquiry.

See Create an enquiry.

2. Create an estimate.

See Create an estimate.

3. Link the estimate to the enquiry.

To do this, select an estimate in the Link to Estimate field on the Enquiry - Details form.

If you use a parent-child enquiry hierarchy, you can link multiple estimates to an enquiry. See Set up an enquiry hierarchy.

4. Complete the Enquiry - Quotation Details form.

See Enquiry Quotation - Details.

5. Print the Enquiry Quotation report.

To do this, click the Actions button on the Enquiry form, and select Print Enquiry Quotation Report.

See also:

Work with reports

List of reports

Find and edit an enquiry

1. Open the Search form from the sidebar menu.

To do this, go to Enquiries & Estimating > Enquiry & Quotation.

2. Enter search criteria and click the Search button.

Records that match your search criteria are listed.

3. Double-click a record to edit it.

For complete information, see Find and edit an existing record.

Enquiry reports

You can access reports from the sidebar menu. Go to Enquiries & Estimating > Enquiries & Estimating Reports.

See also:

Work with reports

List of reports

What's next?

If an initial enquiry leads to your company winning a contract for work, you can continue on to produce a detailed estimate.

See About estimates.

Fields and buttons

Enquiry - Details

When a customer contacts you to request a quotation, use this form to enter basic details about the enquiry. You can specify the status of the enquiry, customer contact details, links to any associated estimates, and the type of building involved along with details of the area and weight of material required.

Fields

|

Field

|

Description

|

|

Status

|

When you first create an enquiry, the status is set to Open. When the enquiry is complete, you can set it to Closed so that it no longer appears on the search form.

|

|

Enquiry

|

This field is automatically populated if the auto-naming/numbering option is turned on in Enquiries & Estimating Options; otherwise, type in a unique name for the enquiry.

|

|

Customer

|

Select a customer from the drop-down list. You can also use the  button to search for a customer or the button to search for a customer or the  ellipsis button to create a new customer. ellipsis button to create a new customer.

See Create a customer record.

|

|

Facility

|

This field is populated when you select a customer. You can change it if necessary.

See About facilities.

|

|

First Name, Surname, Job Title, Telephone, Cell/Mobile, Fax, Email, Address Type, Address, ZIP/Postal Code, Country

|

These fields are populated when you select a customer. You can change them if necessary.

|

|

Salesman

|

Select the name of the sales person from the drop-down list. You can also use the  ellipsis button to create a new sales person. ellipsis button to create a new sales person.

|

|

Estimator

|

Select the name of the estimator from the drop-down list. You can also use the  ellipsis button to create a new estimator. ellipsis button to create a new estimator.

|

|

Parent Enquiry

|

You can build an enquiry hierarchy where several child enquiries are linked to a parent enquiry. You can link an estimate to each of the child enquiries. These are listed in the parent enquiry. For full information, see Set up an enquiry hierarchy.

|

|

Link to Estimate

|

When a customer makes an enquiry, you typically respond by creating an estimate for them. Use this field to link to an estimate that is associated with this enquiry. Alternatively, you can populate the Link to Enquiry field on the Estimate form.

You cannot link an estimate to a parent enquiry.

|

|

Enquiry Received

|

This field is automatically populated with today's date. You can change it if necessary.

|

|

Tender Return Date

|

Specify the date by which you are expected to return the tender.

|

|

Date Declined

|

Specify the date on which you declined to submit a tender.

|

|

Order Start Date

|

Specify the date by which the purchasing department should start to place orders.

|

|

Steel Start Date

|

Specify the date on which fabrication should begin so that you can meet the customer's expected delivery date.

|

|

Currency

|

This field is populated when you select a customer. You can change it if necessary.

|

|

Enquiry Category

|

Select a category from the drop-down list. You can also use the  ellipsis button to create a new category, for example, Full or Design. ellipsis button to create a new category, for example, Full or Design.

|

|

Project

|

Type in the name of the project for which you have been asked to tender.

|

|

Location

|

Type in the geographical location of the project, for example the town and county.

|

|

Sales Area

|

Select a sales area from the drop-down list. You can also use the  ellipsis button to create a new area, for example, South East or Midlands. ellipsis button to create a new area, for example, South East or Midlands.

|

|

Building Type

|

Select a building type from the drop-down list. You can also use the  ellipsis button to create a new type, for example, Miscellaneous steelwork or Handrail and balustrade. ellipsis button to create a new type, for example, Miscellaneous steelwork or Handrail and balustrade.

|

|

Enquiry Size

|

Specify the total surface area of steelwork expected for this project. This is usually indicated on the customer's enquiry documents.

|

|

Enquiry Weight

|

Specify the total weight of steelwork expected for this project. This is usually indicated on the customer's enquiry documents.

|

Grid

If this is a parent enquiry, the child enquiries are listed here.

If this is not a parent enquiry, the grid is not populated.

See Set up an enquiry hierarchy.

Actions button

|

Option

|

Description

|

|

Print Enquiry Report

|

Prints the enquiry details.

|

|

Print Enquiry/Quotation Report

|

Prints the quotation details.

|

|

Email Enquiry Report As PDF

|

This option makes a PDF version of the report, which is attached to a blank email using your default email system.

|

|

Email Enquiry/Quotation Report As PDF

|

This option makes a PDF version of the report, which is attached to a blank email using your default email system.

|

Enquiry - Design Details/Contacts

Use this form to record contact details for the people who are involved in the project. You can also specify the type of work to be carried out and the period during which the design work is to be undertaken.

Fields

|

Field

|

Description

|

|

Design Type

|

Select a design type from the drop-down list. You can also use the  ellipsis button to create a new type, for example, Build Only, Design Only or Build and Design. ellipsis button to create a new type, for example, Build Only, Design Only or Build and Design.

|

|

Project Manager, Designer, Architect, Engineer, Quantity Surveyor

|

Select the key people who will work on this project from the drop-down lists. You can also use the  ellipsis button to create new contacts. ellipsis button to create new contacts.

|

|

Design Start Date

Design Finish Date

|

Specify the dates on which the design work will start and finish.

|

Customer Project People Grid

Use this grid to record the customer contacts that are involved in the project. You can add existing contacts to the list or define new ones. See Add customer contacts.

Buttons

The Actions button options are the same as those on the Enquiry - Details form.

Enquiry - Final Details

Use this form to record information about the project when the details have been finalised.

Fields

|

Field

|

Description

|

|

Bid Status

|

Select a status from the drop-down list. You can also use the  ellipsis button to create a status. The following default options are available: ellipsis button to create a status. The following default options are available:

§ Won

The bid was successful.

§ Lost

The bid was not successful.

§ Unknown

Either the bid is still being processed or you have decided not to submit a quotation. This is the default status.

|

|

Bid Date

|

Specify the date on which the quotation/bid was submitted.

|

|

Date Won

|

Specify the date on which you were notified of your successful bid.

|

|

Final Weight

|

Shows the total weight of the project as determined by the linked estimate(s).

|

|

Final Area

|

Shows the total area of the project as determined by the linked estimate(s).

|

|

Final Value

|

Shows the total value of the project as determined by the estimate(s).

|

|

Percent Return

|

Specify the percentage of the total value expected as profit.

|

Buttons

The Actions button options are the same as those on the Enquiry - Details form.

Enquiry - Quotation Details

This form allows you to specify the text to include the Enquiry Quotation report. Each of the four main fields can be included or excluded from the report using the Include in Report check boxes. You can type directly into the fields or use the Predefined Notes buttons to add standard text (see Add notes to a record).

Fields

|

Field

|

Description

|

|

Terms and Conditions

Include in Report

Predefined Notes

|

Specify the legal clauses that you want to include in the report. Please note that your terms and conditions must be approved by a legal body.

|

|

Quotation Scope

Include in Report

Predefined Notes

|

Specify the scope of the services that will be provided by your company.

|

|

Quotation Includes

Include in Report

Predefined Notes

|

Specify the details of specific items that are included in your quotation.

|

|

Quotation Excludes

Include in Report

Predefined Notes

|

Specify details of specific items that are excluded from your quotation.

|

|

Quotation Weight and Value

|

This field is automatically populated from the linked estimate(s) and can be used in the quotation by selecting the Use Final Weight for Quotation check box and the Use Final Value for Quotation check box.

If you want to round either of the figures up or down, type the amounts into the Adjusted Weight and Adjusted Value fields.

|

Buttons

The Actions button options are the same as those on the Enquiry - Details form.

Enquiry - Key Requirements

The options that are available for each of the fields on this form are user-defined in lookup windows. You can select a previously defined option from the drop-down list, or use the  ellipsis button to create a new option.

ellipsis button to create a new option.

General fields

|

Field

|

Description

|

|

NDA Agreement

|

If you have a non-disclosure agreement with your customer, you can link it here. Click the  ellipsis button and select the document. Click the View button to open the document. ellipsis button and select the document. Click the View button to open the document.

|

|

Prequalification

|

|

General Scope of Work fields

|

Field

|

Description

|

|

Design

|

Specify the level of design work that is to be undertaken. Examples are:

§ Full design

§ No design

§ Connections only

|

|

Fab

|

Specify whether the project includes fabrication. You may only need to define Yes and No options.

|

|

Prep

|

Specify whether the project includes the preparation of column bases. You may only need to define Yes and No options.

|

|

Erection

|

Specify whether you are going to erect the structure. Examples of the options that you may define are:

§ Supply only

§ Supply and erect

|

|

BIM

|

Specify whether you are supplying a model. You may only need to define Yes and No options.

|

|

Detail

|

Specify who will implement the detailing, for example, Customer or Third Party.

|

|

Paint

|

Specify the required paint finish, for example, Galvanised or Shop Paint PS2.

|

|

Freight

|

Specify whether freight costs should be considered. You may only need to define Yes and No options.

|

|

Other

|

Use these fields to specify other key requirements.

|

Materials fields

|

Field

|

Description

|

|

LEED

|

|

|

Unique Material Criteria and Inspection

|

|

|

Buy American

|

|

|

Domestic Only

|

|

Fabrication Erection fields

|

Field

|

Description

|

|

Paint Certifications

|

|

|

Erector Certification

|

|

|

Local Workforce Participation

|

|

|

Shop Certifications

|

|

|

Shop NDT

|

|

|

Inspections (by SchM/W/SBE)

|

|

|

Participation

|

|

|

Market Retention

|

|

Administration Requirements fields

|

Field

|

Description

|

|

Sales Tax

|

Specify the sales tax, if applicable. Examples are 6% or 20%VAT.

|

|

Warranty Period

|

Specify the length of time for which the work is under warranty. Examples are:

§ 6 months

§ 12 months

§ 10 years

|

|

LD's/Penalties

|

Specify whether you will pay liquidated damages to the customer in the event of a breach of contract or late delivery. You may only need to define Yes and No options, or you could specify the amounts payable to the customer after a certain time.

|

|

Bid Bond

|

Specify whether you will provide a bid bond to the customer to guarantee that you will undertake the project if selected. You may only need to define Yes and No options, or you could specify the value of the bond.

|

|

Performance Payment Bands

|

Specify whether your customer will pay you a bonus if a phase of the project is completed ahead of schedule. You may only need to define Yes and No options, or you could specify the bands and the amounts payable.

|

|

Other Taxes

|

Specify any other taxes.

|

|

Payment Terms

|

Specify the payment terms, for example, Payment In Advance or Net 90.

|

|

Retention Terms

|

Specify the monetary amount that your customer intends to retain to fix defects. Examples are:

§ 5% for 12 months

§ 1% for 6 months

|

|

Certified Payroll

|

|

|

OCIP/CCIP

|

Specify whether there is an Owner Controlled Insurance Program (OCIPs) or Contractor Controlled Insurance Program (CCIPs) in place for the project. You may only need to define Yes and No options, or you could specify the bands and the amounts payable.

|

Buttons

The Actions button options are the same as those on the Enquiry - Details form.

Enquiry - Project Meetings

Fields

There are five areas on this form, where you can note future project meetings that you have scheduled with your customer along with an agenda for the meeting. When the meeting has taken place, you can also record the minutes of the meeting here. You can type directly into the fields, or you can use predefined notes (see Add notes to a record).

Buttons

The Actions button options are the same as those on the Enquiry - Details form.

Chapter 4

What's in this chapter?

About estimates

Create an estimate

Add a subsection to the estimate

Add a steel item to the subsection

Add labour for a steel item

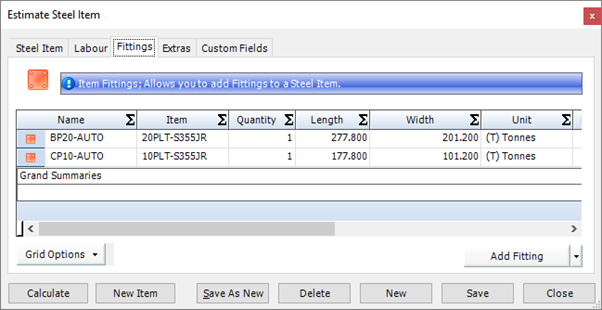

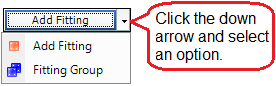

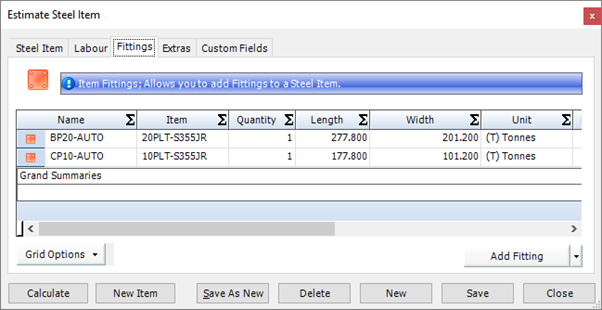

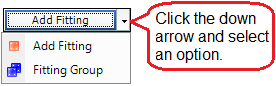

Add a fitting to a steel item

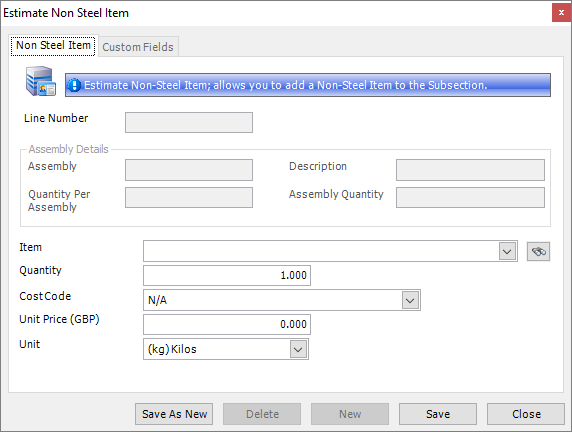

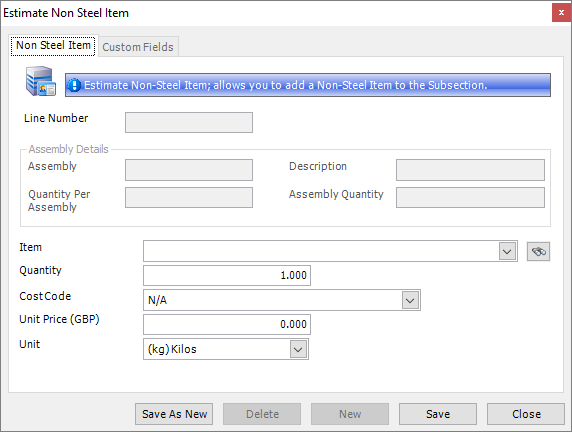

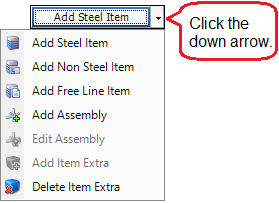

Add a non steel item to the subsection

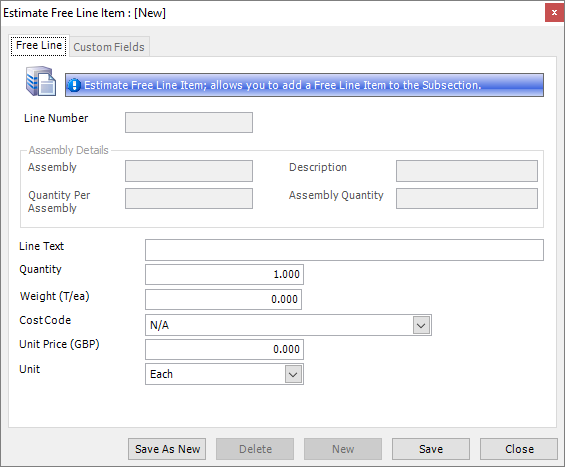

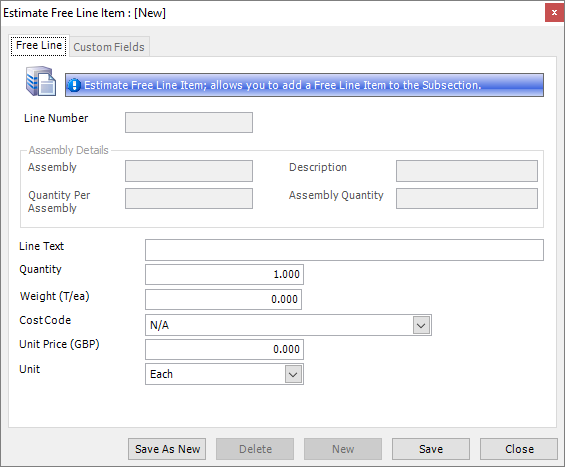

Add a free line item to the subsection

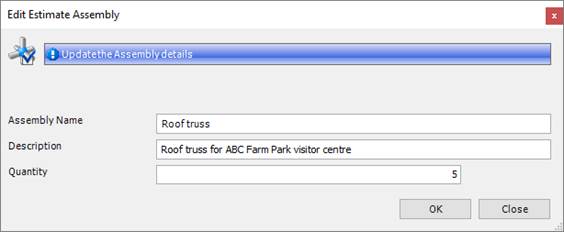

Add an assembly to the subsection

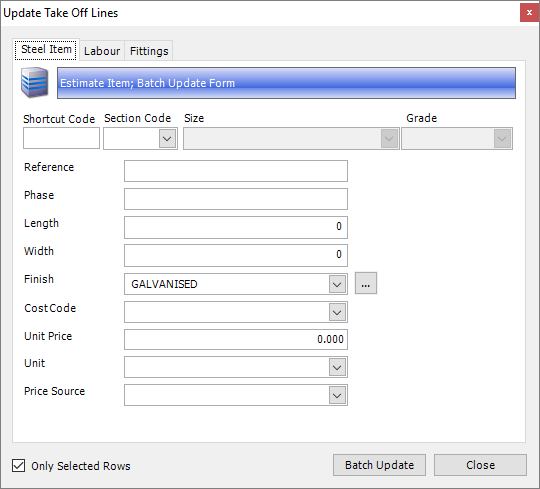

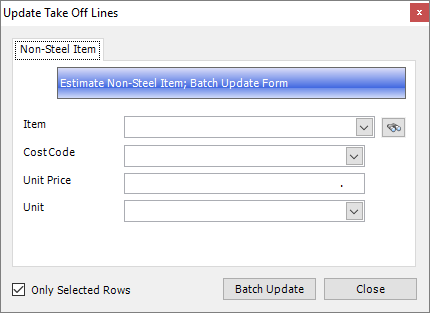

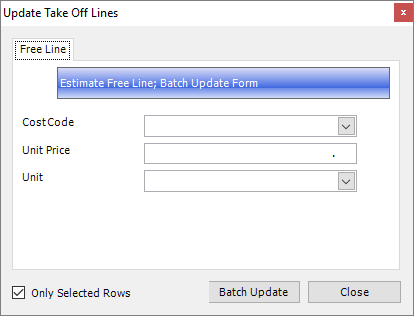

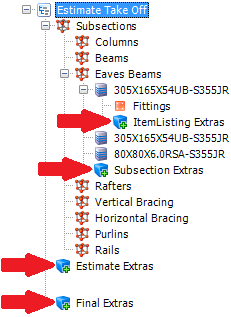

Batch update take-off or BOQ lines

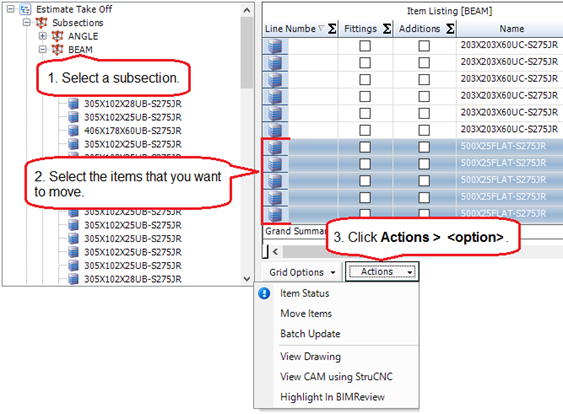

Move items to another subsection

Add extras

Import an estimate

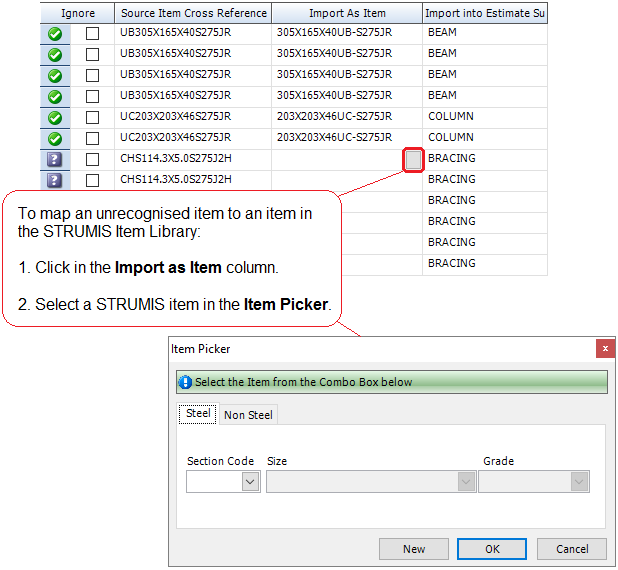

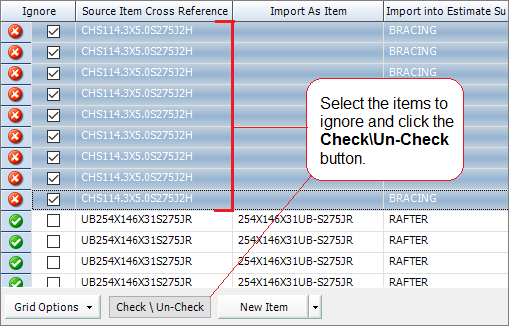

Resolve unrecognised items

Find and edit an estimate

Estimate reports

What's next?

Fields and buttons

About estimates

The STRUMIS Estimating module allows you to produce cost estimates using a drawing take off or bill of quantities method.

Take off estimating is the typical way of producing a list of material requirements from drawings, which are then weighted and priced. You can include additional material allowances (by percentage or value), and allow for labour times and costs by applying material or labour extras from a customisable library.

Bill of quantity estimating is similar to take off estimating. It is prepared using a “taking off” process in which the cost of a building or other structure is estimated from measurements in the architect's drawings. These are used to create a cost estimate based on the area of walls and roofs and the numbers of doors and windows. This method combines labour and material costs into a single rate that is then adjusted with regard to material quantities.

Access

To access estimates, click the Estimate button on the Contract Ribbon. Alternatively, from the sidebar menu, go to Enquiries & Estimating > Estimate.

When you create or edit an estimate, you will use the Estimate form.

Create an estimate

The following instructions tell you how to create an estimate.

1. Go to Enquiries & Estimating >Estimate.

A list of existing estimates is displayed.

2. Click New.

The Estimate - Details form is displayed.

It has the following tabs:

§ Details

Specify basic information for the estimate. This includes a description, whether the estimate is a take off or a bill of quantities, and a list of quotes that are associated with the estimate.

See Estimate - Details for a full list of the fields and buttons on this tab.

§ Take Off or BOQ

This form is the main hub of the estimating module. It allows you to add and edit steel items, non-steel items and assemblies to the estimate. You can also add free line items, labour, fittings and extras.

See Estimate - Take Off for a full list of the fields and buttons on this tab.

§ Data

Specify paths to CAD, CAM, and BIMReview files for the estimate.

See Estimate - Data for a full list of the fields and buttons on this tab.

§ Hidden Fields

Use this form to hide some of the estimating fields that you do not use.

See Estimate - Hidden Fields for a full list of the fields and buttons on this tab.

§ Custom Fields

If you need to collect data that is relevant to this type of record, but there are no appropriate fields, use this form to define your own custom fields.

See Define custom fields for a record for a full list of the fields and buttons on this tab.

§ Attachments

Use this form to attach external documents to a STRUMIS record.

See Attach external documents to a record for a full list of the fields and buttons on this tab.

§ Information

Use this form to view the creation date of the record, the date when it was last updated, and the users who made the changes.

See View basic information about a record for a full list of the fields and buttons on this tab.

3. Enter basic details for the estimate. This includes typing in a description, specifying whether the estimate is a take off or a bill of quantities (this is important as you cannot change it after you save the estimate for the first time), and specifying whether you will be adding fittings and labour costs.

4. Click Save.

The estimate details are saved and you can continue on to add estimate items on the Take Off or BOQ form.

Add a subsection to the estimate

You can add a subsection to an estimate in several ways:

§ Add an individual subsection

§ Add a subsection set

§ Copy an existing subsection from any estimate into the current estimate

These are described in more detail in the following sections.

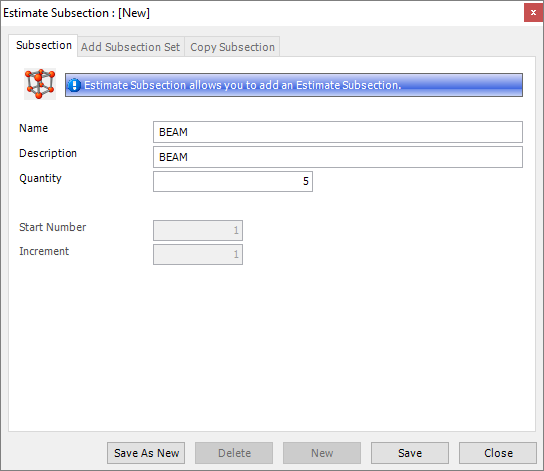

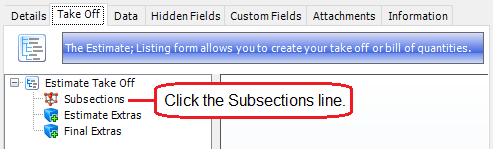

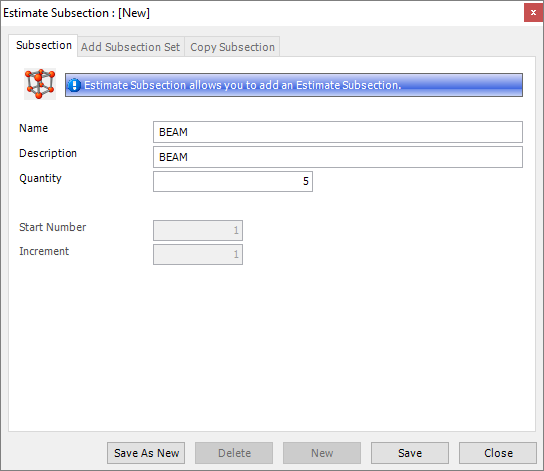

Add an individual subsection

Use the following instructions to add a subsection to an estimate:

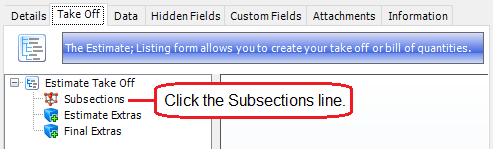

1. On the Estimate - Take Off or BOQ form (depending on the setting for the Estimate Type on the Estimate - Details form), click the Subsections line.

2. Click the Add Subsection button.

The Estimate Subsection form is displayed.

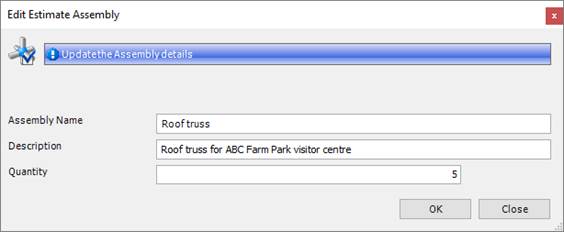

3. Give the subsection a name and description, specify the quantity that you need, and click Save.

You can now add steel items, non-steel items, free line items and assemblies to the subsection.

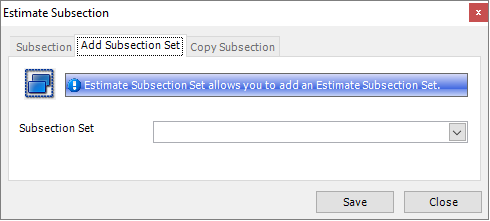

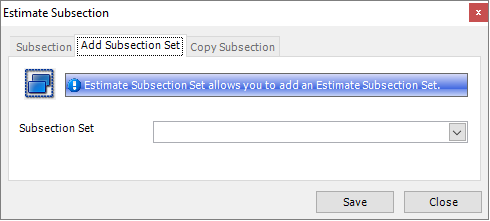

Add a subsection set

Use the following instructions to add a subsection set to an estimate.

See About subsection sets).

1. Click the Subsections line, as above.

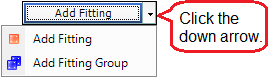

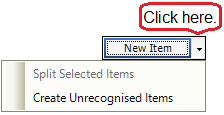

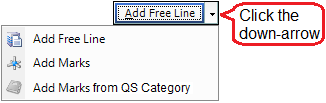

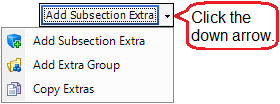

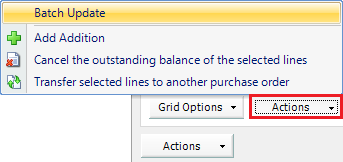

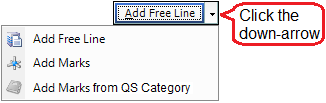

2. Click the down-arrow to the right of the Add Subsection button as shown below:

3. Select Add Subsection Set.

The Estimate Subsection - Add Subsection Set form is displayed.

4. Select a subsection set from the drop-down list and click Save.

The subsections from the group are added to the estimate.

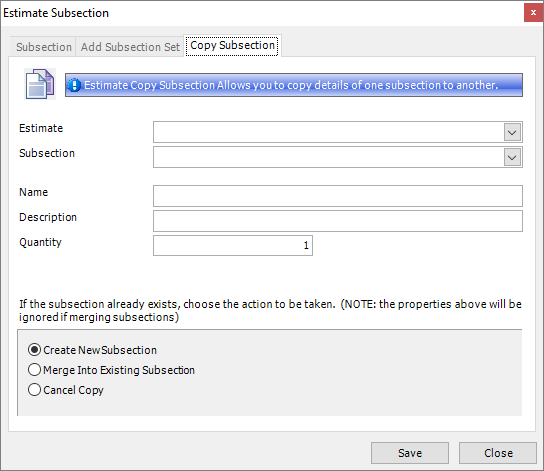

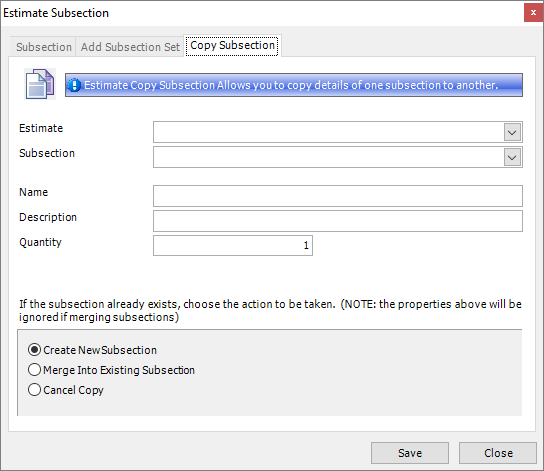

Copy existing subsections

Use the following instructions to copy subsections from another estimate.

1. Click the Subsections line, as above.

2. Click the down-arrow to the right of the Add Subsection button as shown below:

3. Select Copy Subsection.

The Estimate Subsection - Copy Subsection form is displayed.

4. Select the estimate and subsection that you want to copy.

Specify a name, description and quantity for the subsection that you want to create.

Specify what you want to do in the event that the subsection already exists in the current estimate. You can create a new subsection, merge the copied subsection and the existing subsection, or cancel the copy action.

5. Click Save.

The subsection is copied to the current estimate.

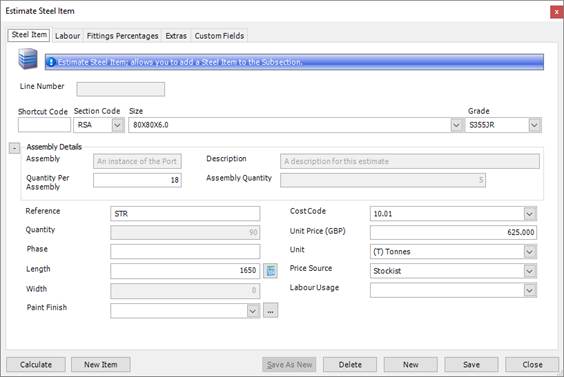

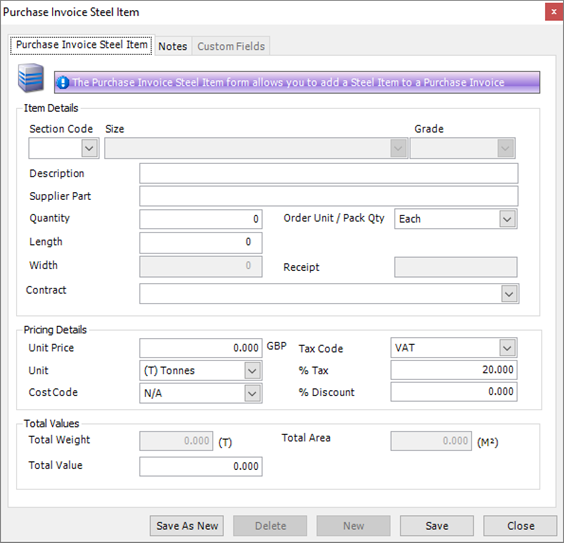

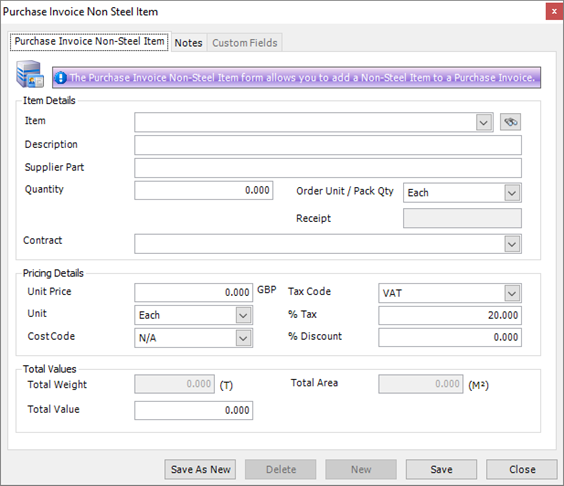

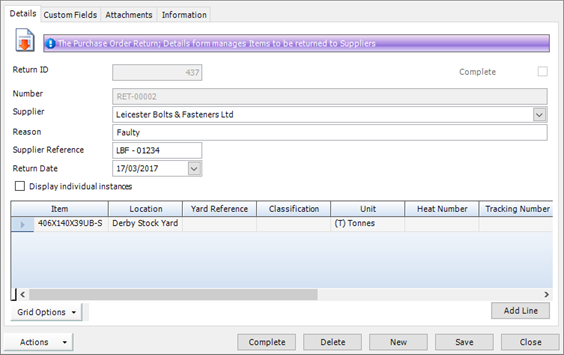

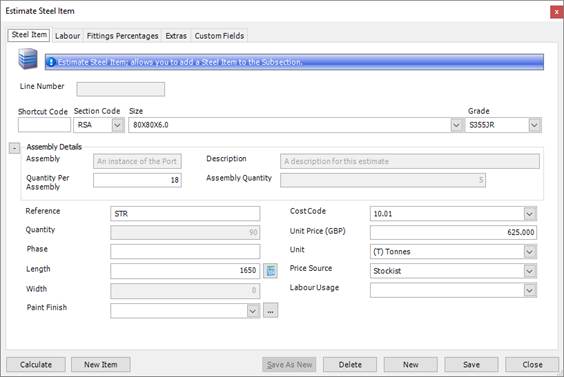

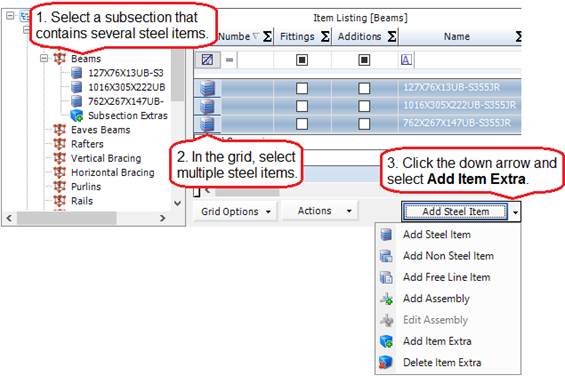

Add a steel item to the subsection

Use the following instructions to add a steel item to a subsection:

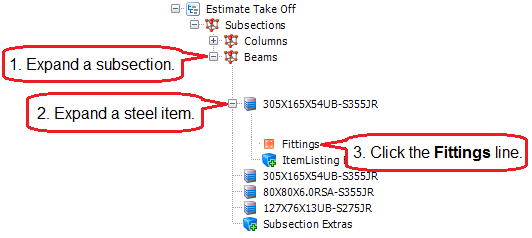

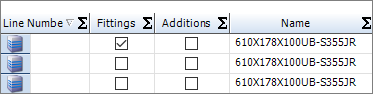

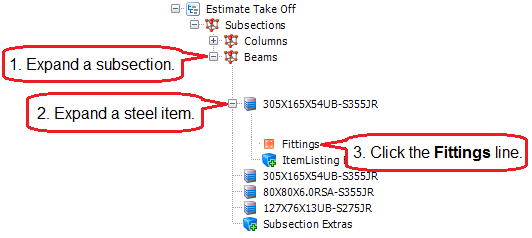

1. On the Estimate - Take Off or BOQ form (depending on the setting for the Estimate Type on the Estimate - Details form), click a subsection.

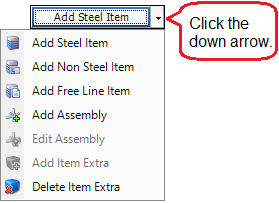

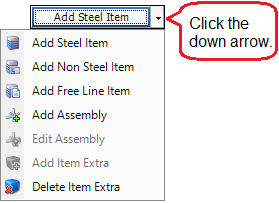

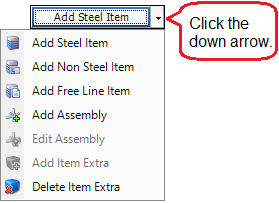

2. Click the Add Steel Item button.

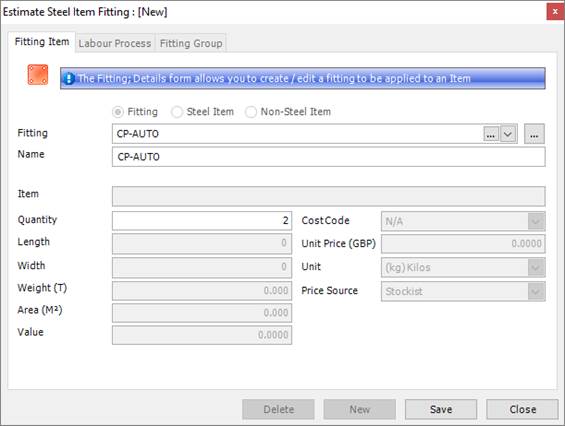

The Estimate Steel Item form is displayed.

3. Use the Section Code, Size and Grade fields to specify the steel item that you want to add to the estimate.

Populate the other fields as required. See

Estimate Steel Item - Steel Item

Estimate Steel Item - Labour

Estimate Steel Item - Fittings

Estimate Steel Item - Extras

4. Click Save.

The steel item is added to the subsection.

|

|

On the Estimate - Take Off or BOQ form, you can edit steel items that have been previously added. To do this, double-click the steel item in the grid.

The Estimate Steel Item - Steel Item form is displayed.

|

Add labour for a steel item

There are two ways to apply labour to a steel item. They are:

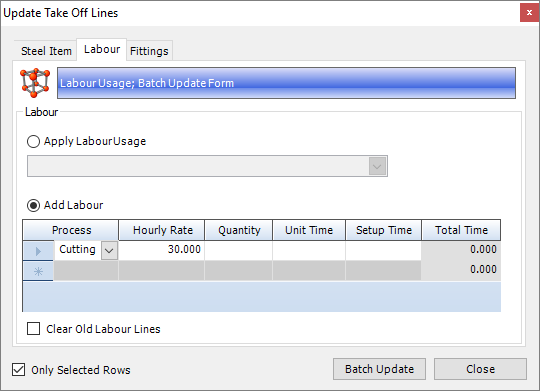

§ Add labour on the Estimate Steel Item - Labour form

§ Add labour automatically by matching the labour usage name and the subsection name

In both cases, you must set the Apply Labour Usages field on the Estimate - Details form to Yes.

The above options are described in more detail in the following sections.

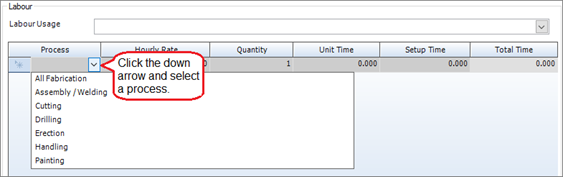

Add labour on the Estimate Steel Item - Labour form

When you add a steel item to a subsection, or when you edit a steel item that was previously added to a subsection, you use the Estimate Steel Item form. You can use the form to add labour for the steel item.

§ To add a labour usage:

Select a labour usage from the Labour Usage drop down list either on the Estimate Steel Item - Steel Item form, or here on the Estimate Steel Item - Labour form. This is the same field, simply displayed in two different places.

The processes that are associated with the labour usage are listed.

Click Calculate, then Save.

§ To add a process:

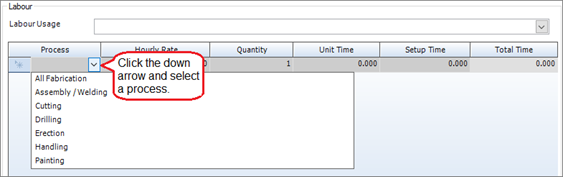

Click the down arrow in the Process column and select a process, as shown below:

Type in an hourly rate, quantity, unit time and setup time if necessary.

Click Calculate, then Save.

§ To delete a process from the list, select the process row and press the Delete key on your keyboard.

Add labour automatically

You can automatically include labour when you add a steel item to a subsection. To do this:

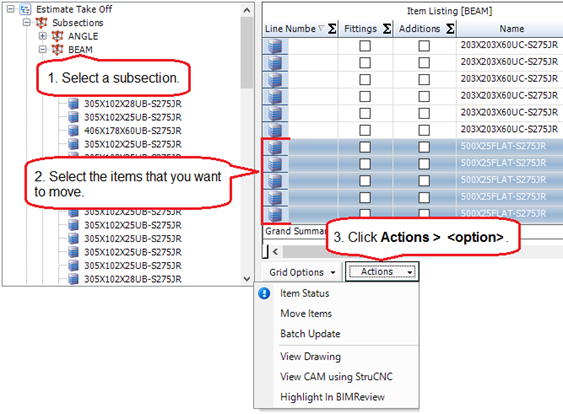

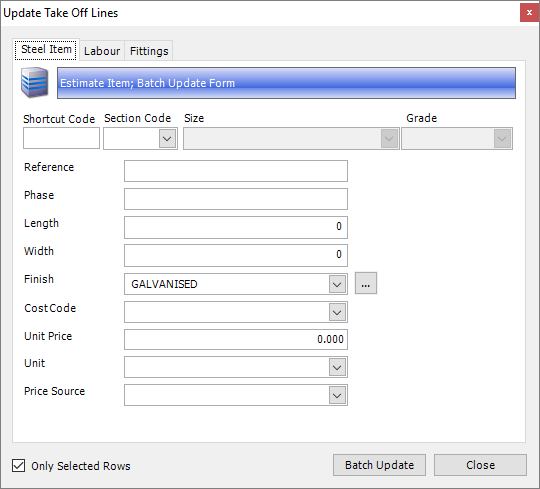

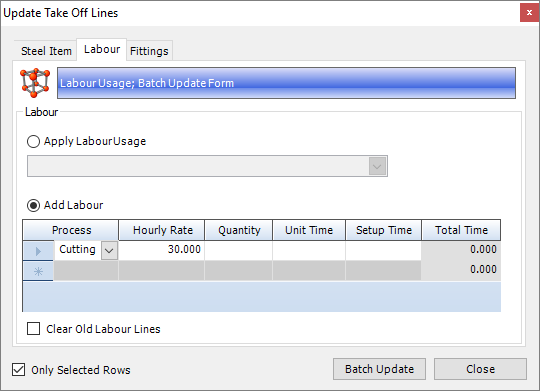

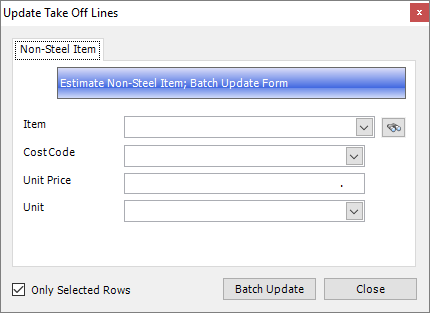

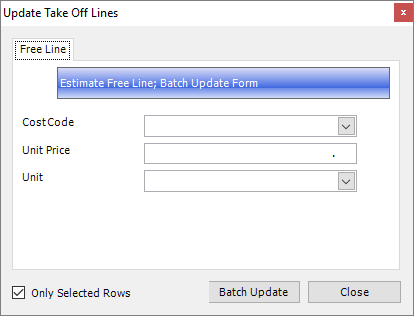

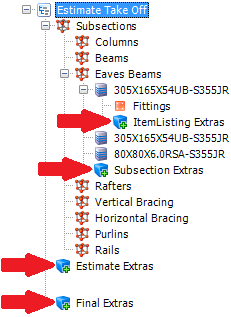

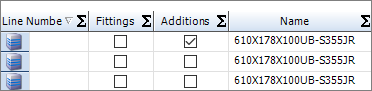

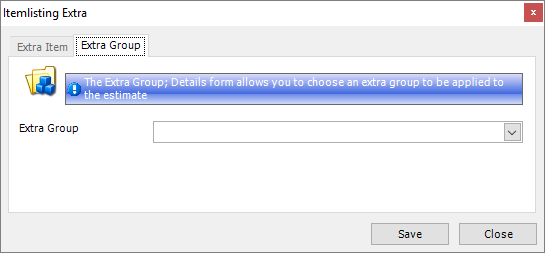

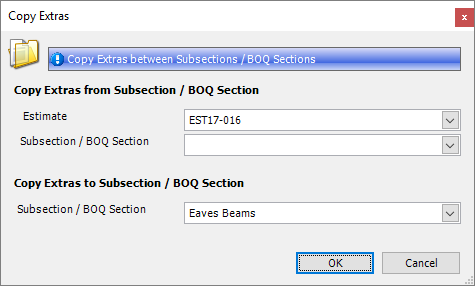

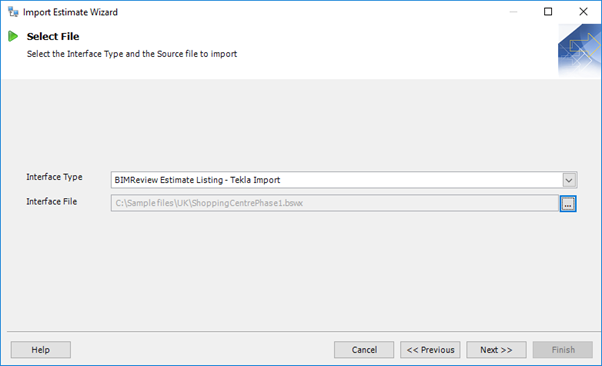

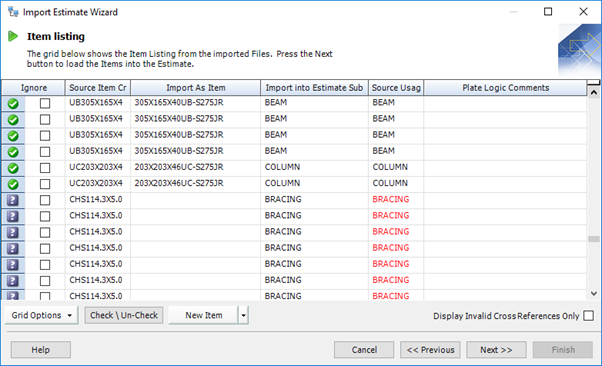

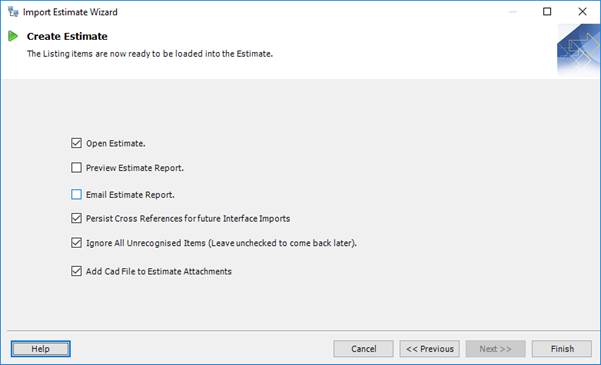

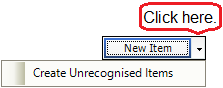

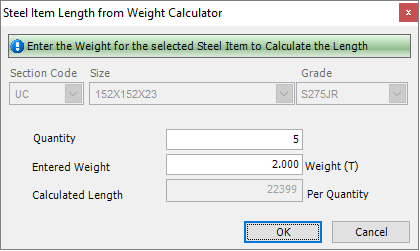

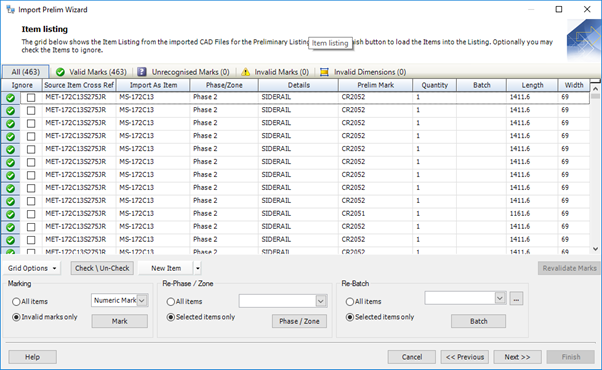

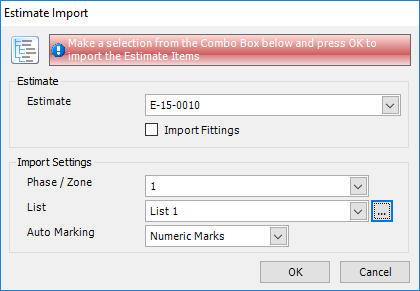

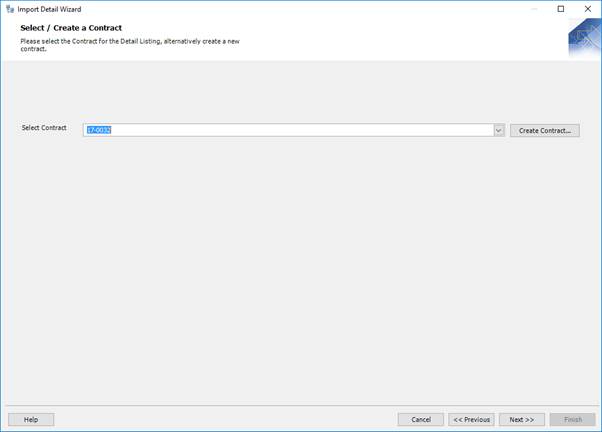

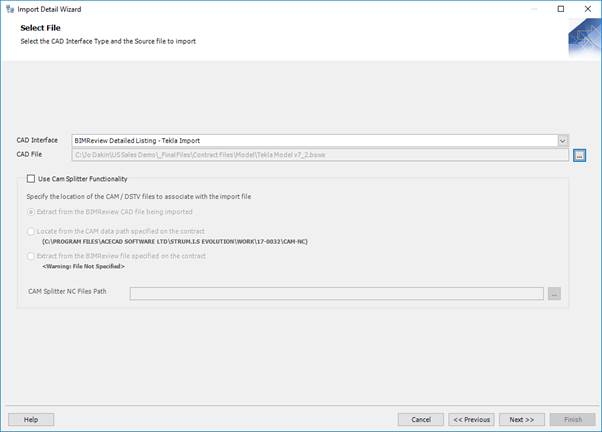

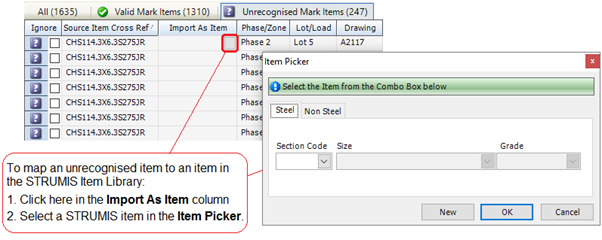

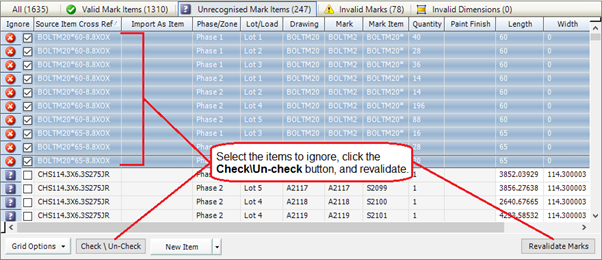

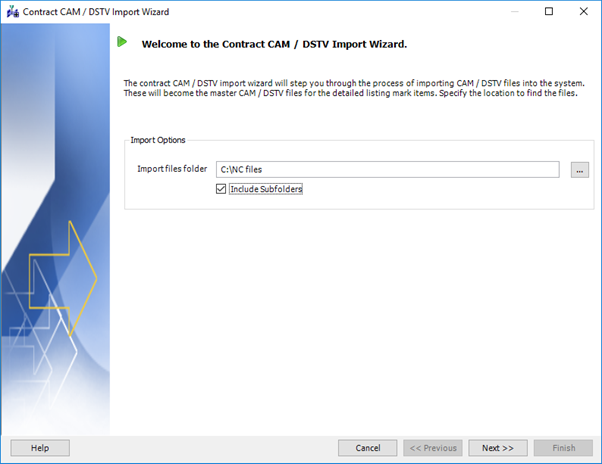

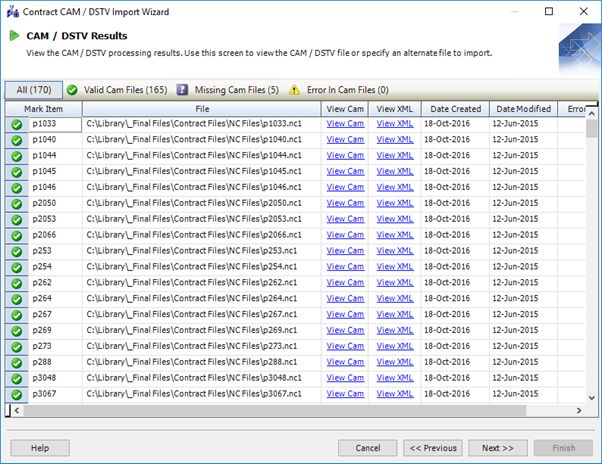

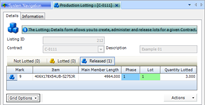

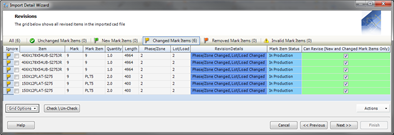

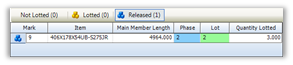

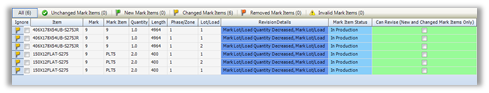

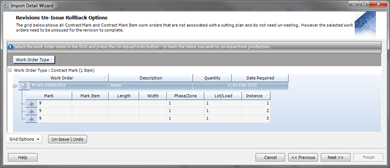

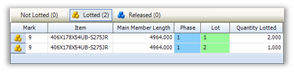

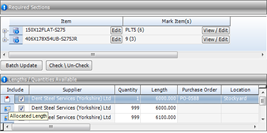

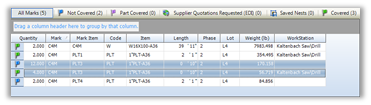

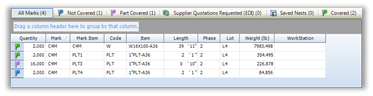

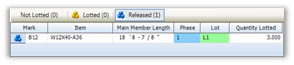

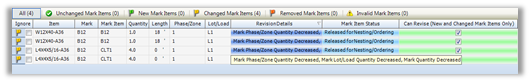

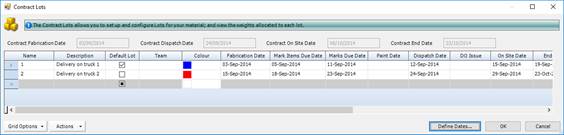

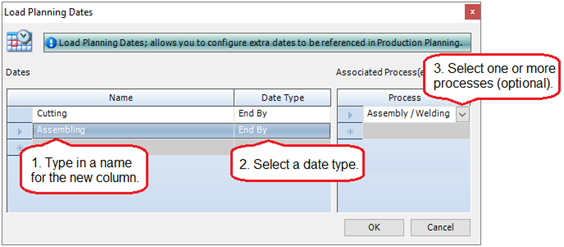

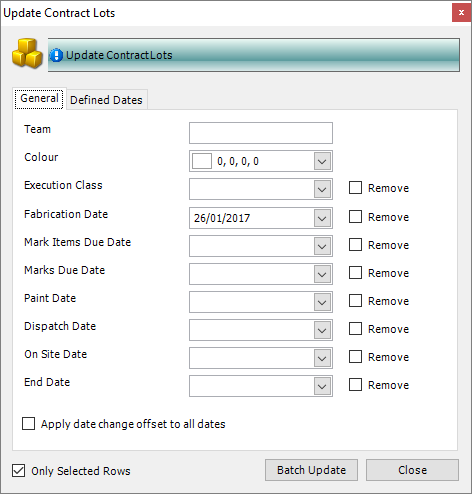

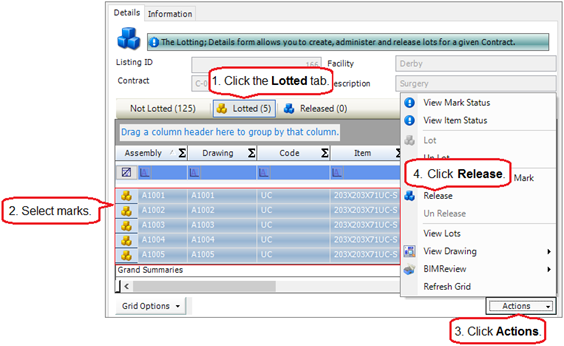

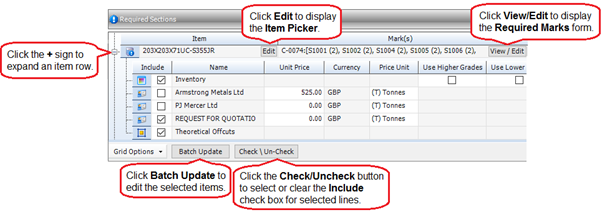

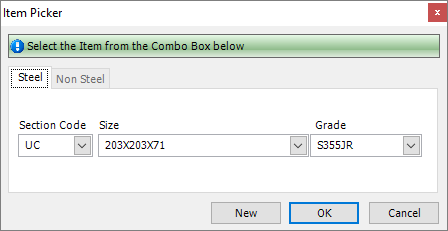

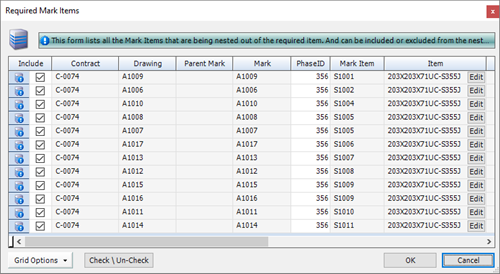

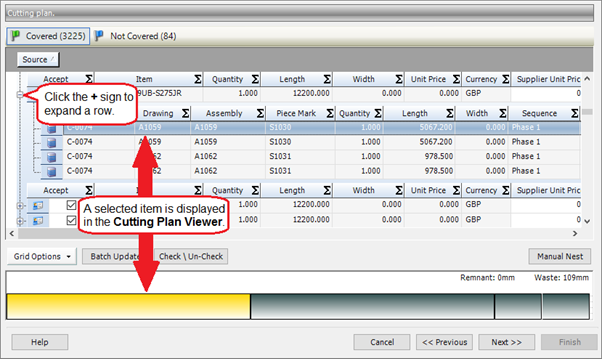

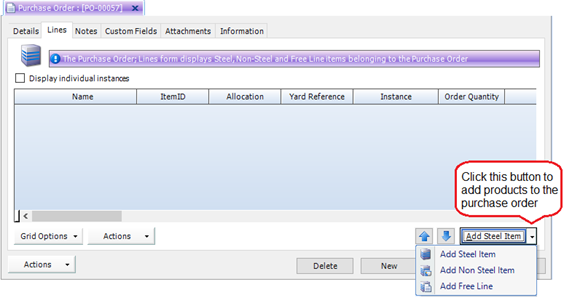

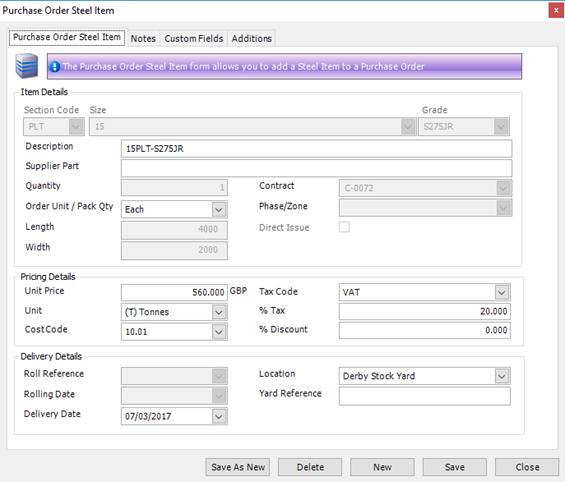

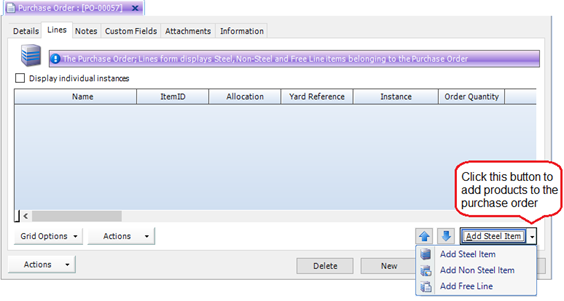

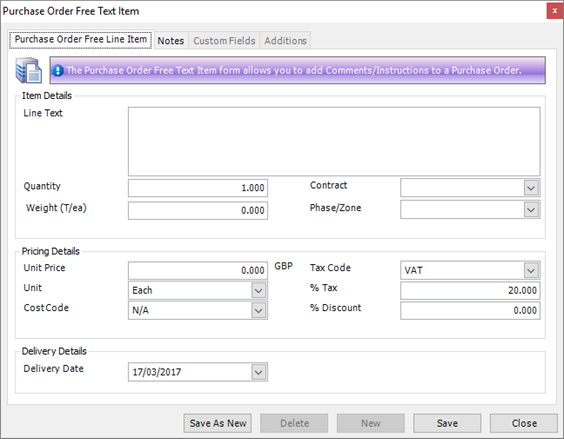

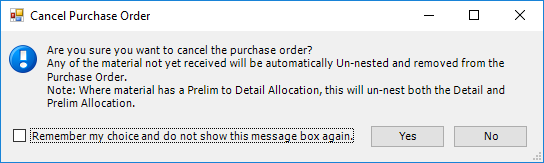

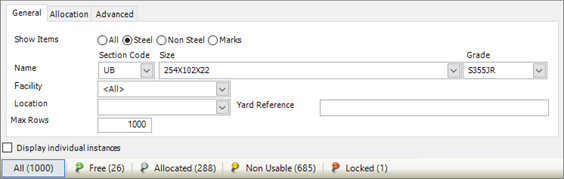

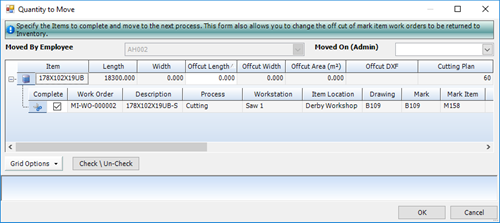

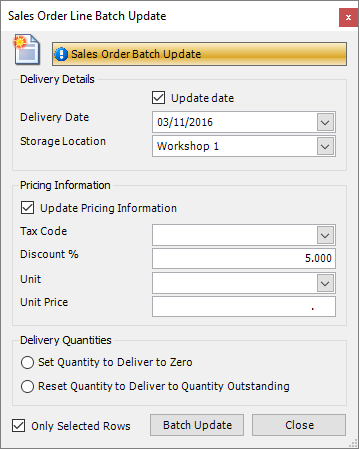

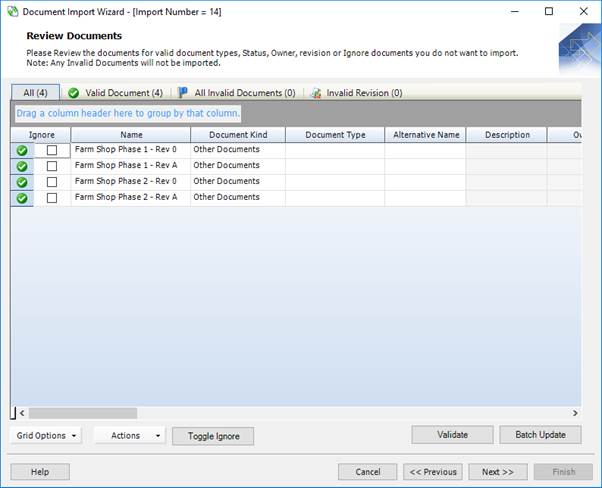

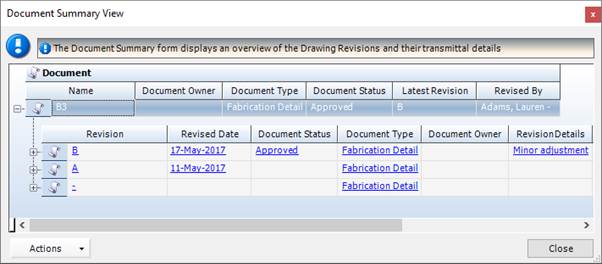

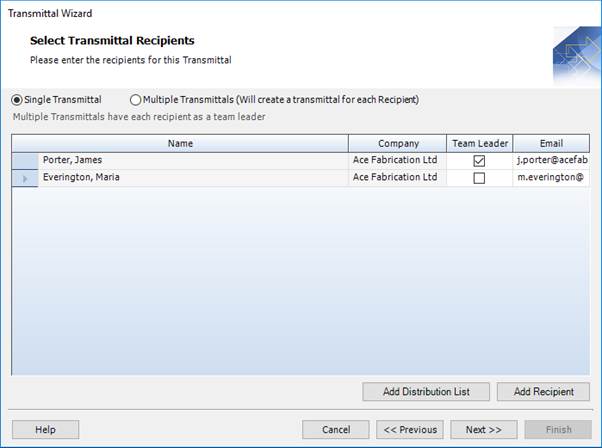

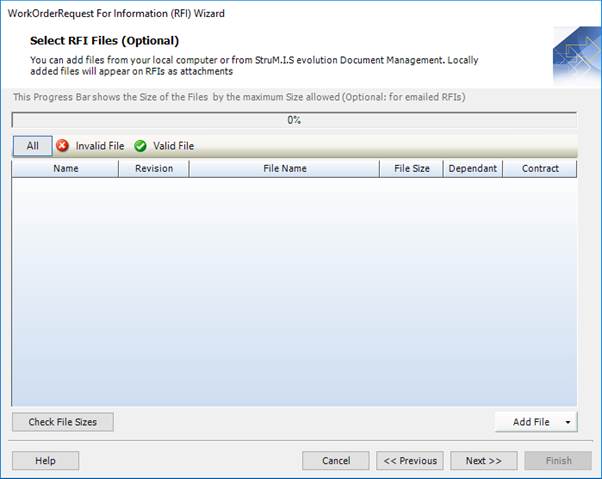

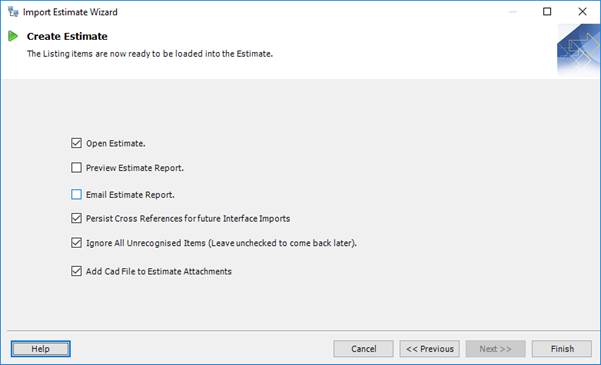

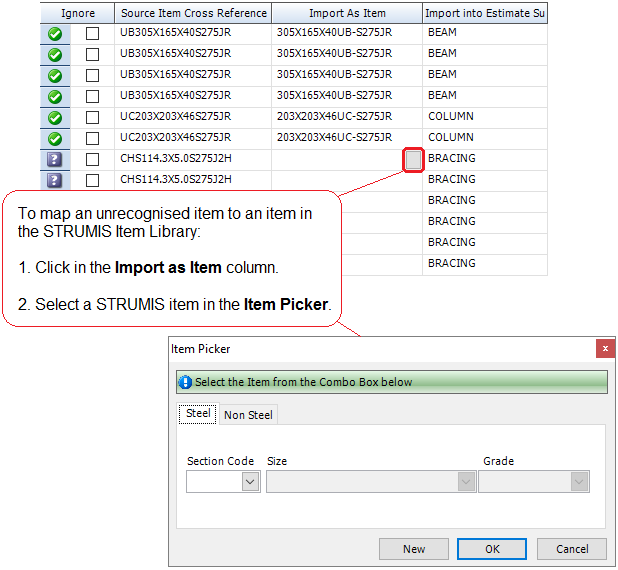

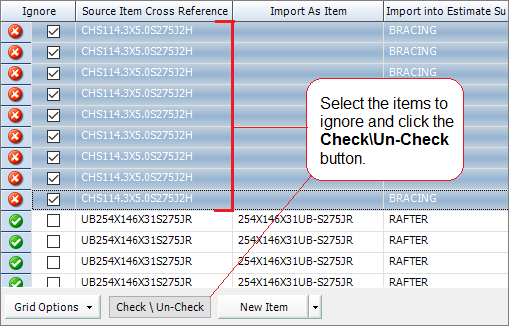

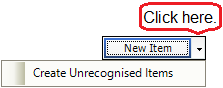

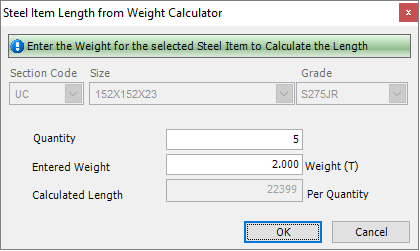

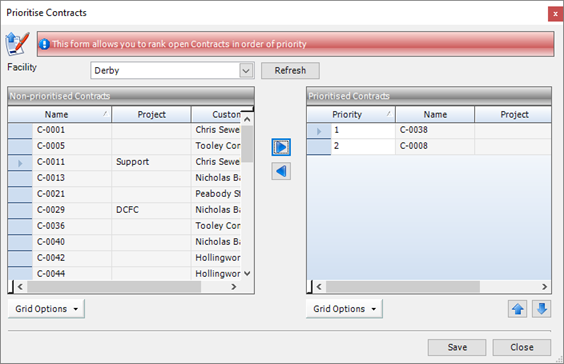

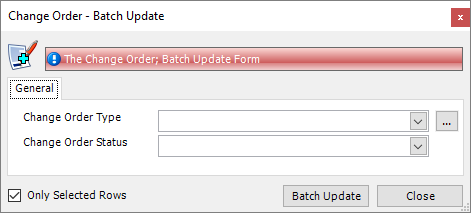

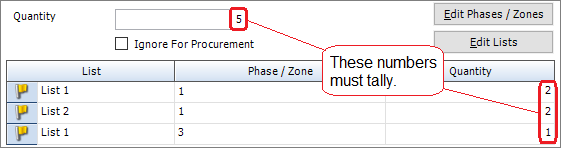

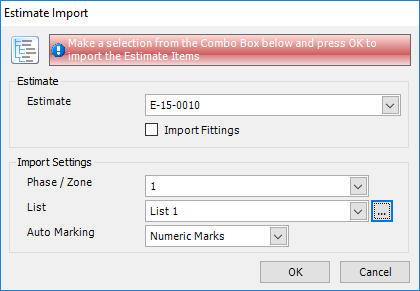

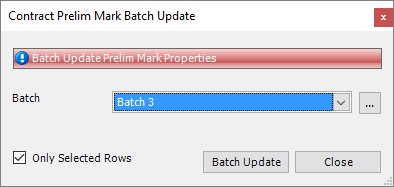

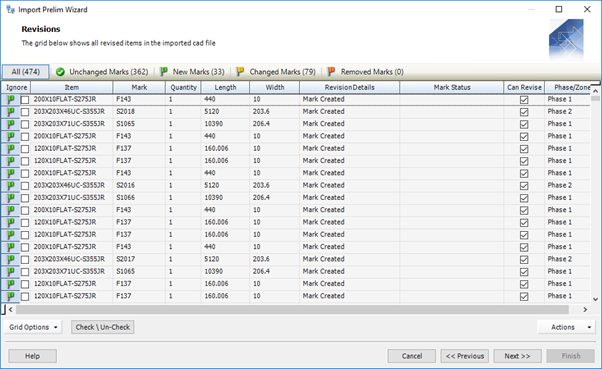

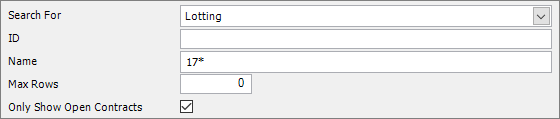

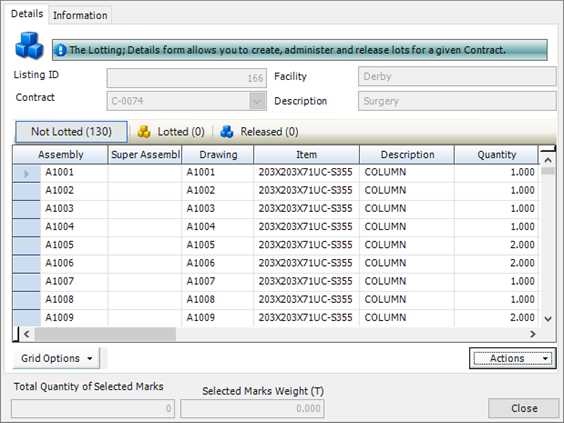

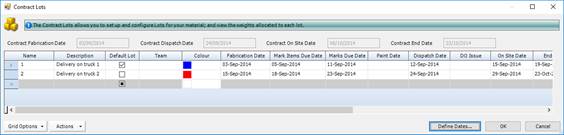

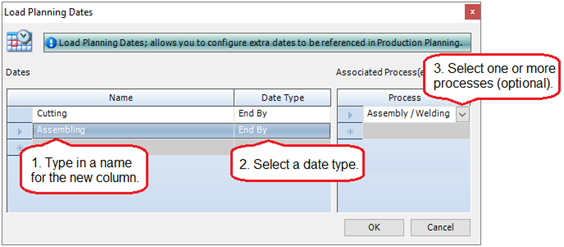

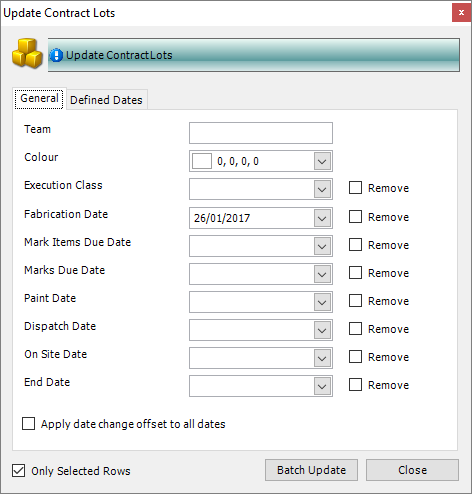

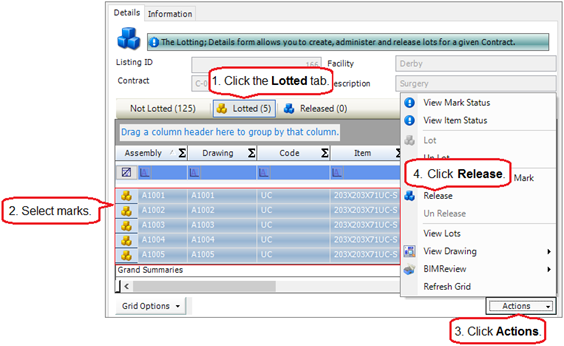

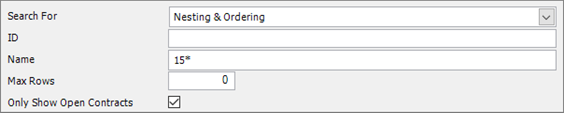

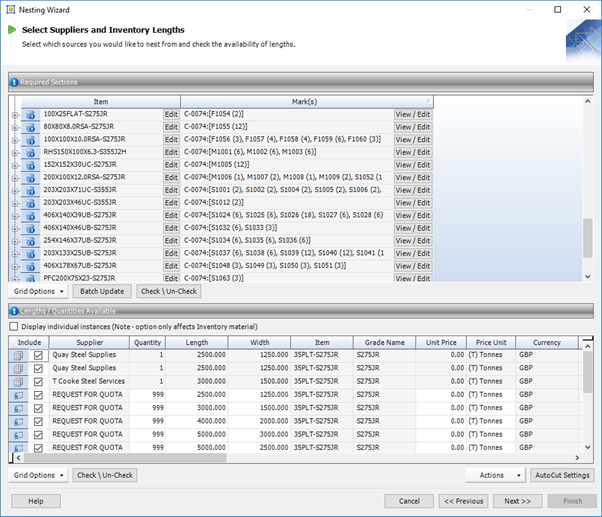

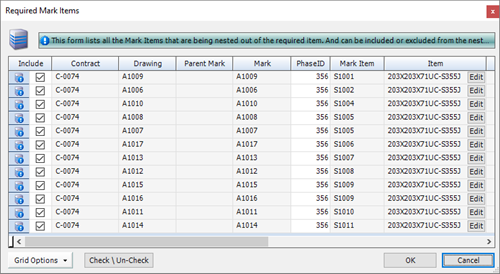

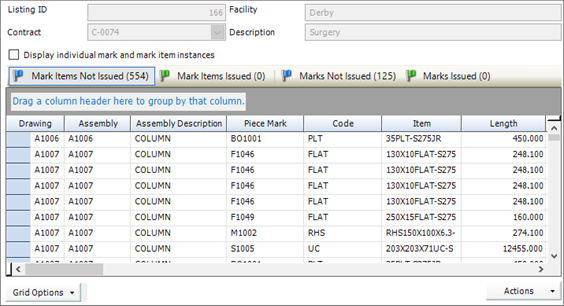

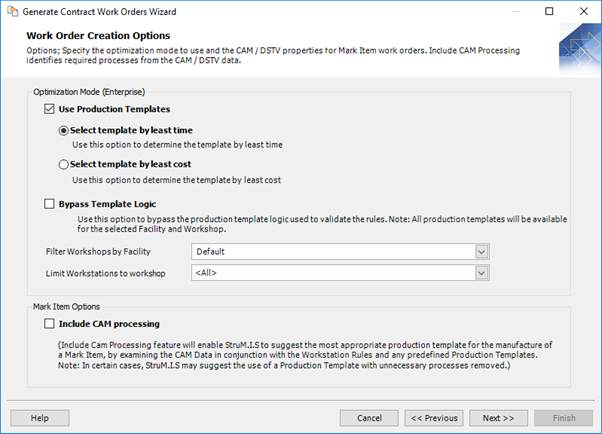

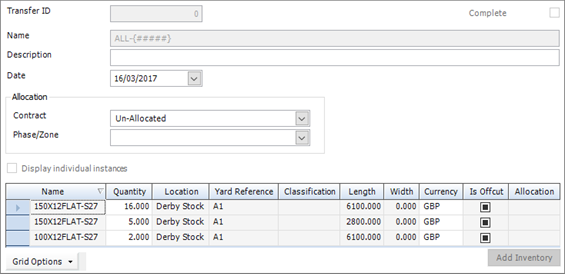

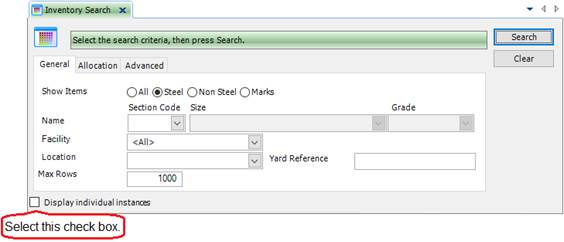

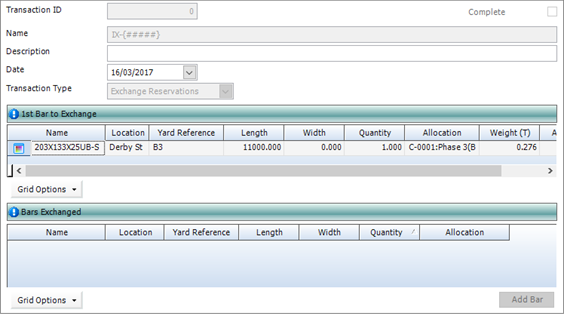

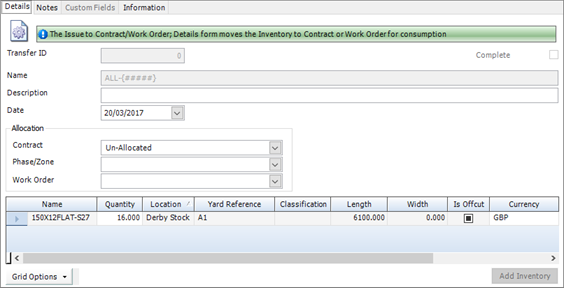

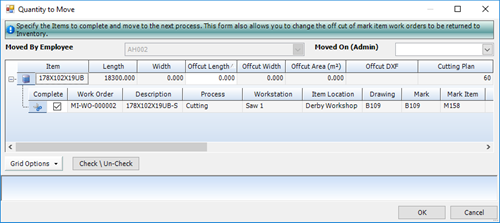

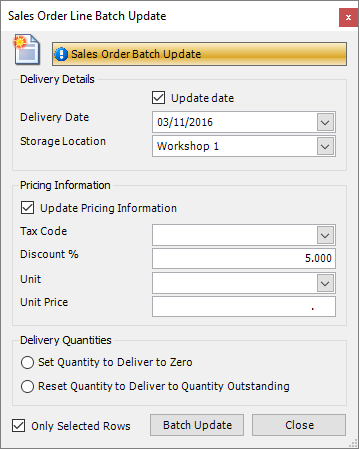

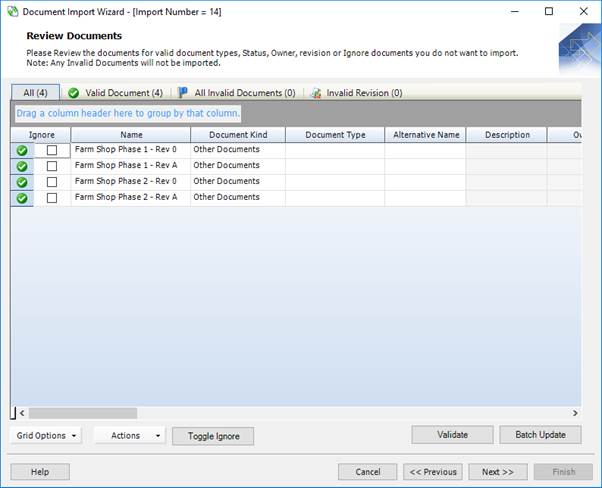

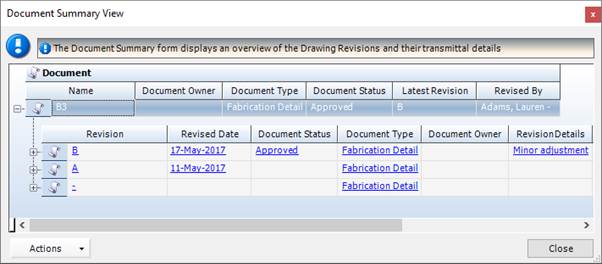

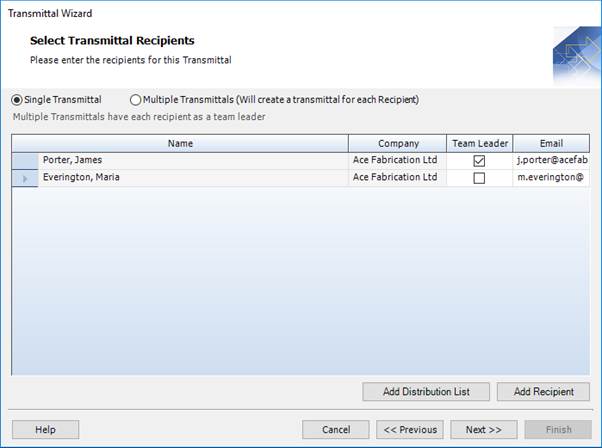

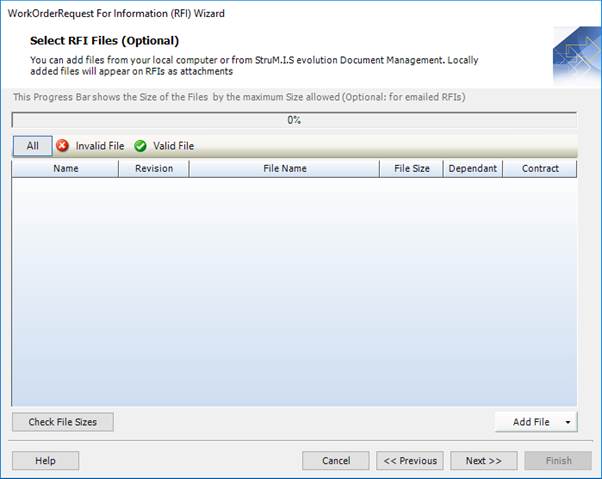

1. Select the Automatically apply labour usages by matching the subsection name check box on the Estimate - Details form.